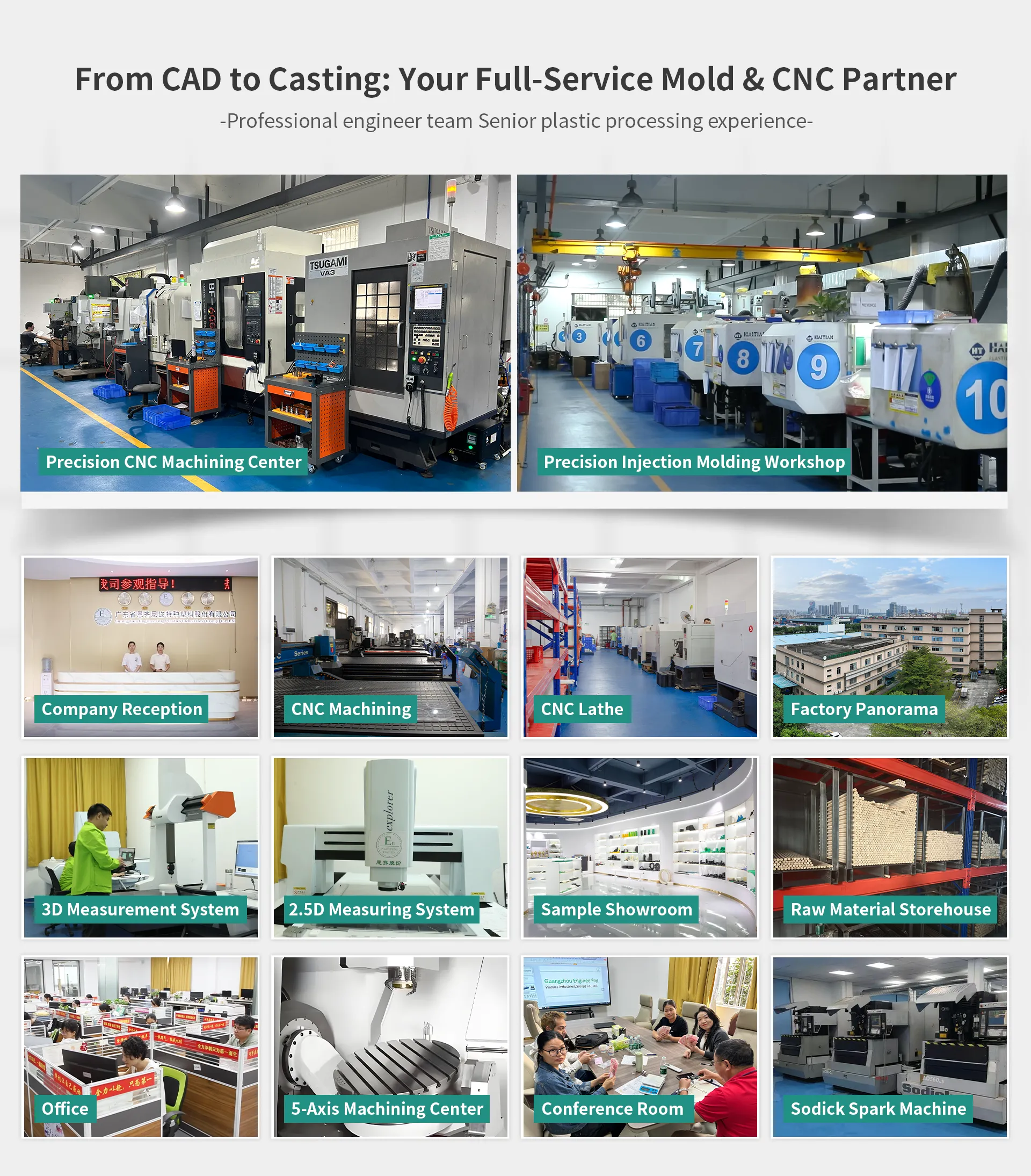

Why manufactureIndustrial machinery partswith EN?

ISO certified

Guangdong Enineering Pastics induties (Group) Co. Ltd.is an lS09001-2015 certified manufacturerthat can guaran-tee top quality parts in an industrythat demands rigorousconsistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size, from one-off engine part prototypes to full production of injection molded headlamp covers.

Range of services

Equal parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Short lead time

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

We have been manufacturing aerospace parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Robotics & automation prototyping and manufacturing with EN

At EN, we provide robotics and automation customers with rapid prototyping and services like CNC machining and Injection Molding. Our expert team has the knowledge and skills to help bring new product concepts to life. For more information on our prototyping capabilities and how we serve the robotics industry, contact us or request a quote today.

What kind ofroboticsautomation partscan we make?

Medical manufacturing processes

EN offers wide range of manufacturing processes for medical prototypes and production parts.

View all services →

CNC Machining

By using CNC milling & turning, we can make a wide range of prototypes and production parts

Injection Molding

We offer low-volume prototype moldings and mass production moldings.

3D Printing

We provide 3D printing services using a range of cutting-edge additive manufacturing technologies for metal or plastic parts

Vacuum Casting

Our low-cost vacuum casting services are suitable for prototyping casings, housings, and tubing for complex robotic assemblies.

Robotics & Automation Part Gallery

For the years we have gathered relevant experience that enables us to handle any robotic projects. Here's the gallery of robotic prototypes and production parts for our worldwide clients.

Get Instant Quote →

Industrial machinery manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for industrial machinery are listed below.

| Best technologies | Manufacturing methods | Benefits | Example parts |

|---|---|---|---|

| CNC machining, rapid tooling | Strong, corrosion-resistant, sterilizable, range of grades | Surgical instruments, Heat exchangers, pumps, tubing |

| CNC machining, rapid tooling, sheet metal | Machinable, strong, range of grades | Cylinder heads, manifolds, Ductwork, housings, bus ducts |

| CNC machining, injection molding | Strong, lightweight, low friction | Casings, housings |

| Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

| Vacuum casting | Transparent, affordable | Casings, housings |

Surface Treatment Methods

We offer a variety of surface treatment methods to meet different industrial application requirements

| Name | Applicable to | Feature | Color | Thickness |

|---|---|---|---|---|

| As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

| Sanding & Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

| Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

| Painted | Metals & Plastics | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.1mm |

| Powder coat | Metals | Matt, Gloss & Texture | colors can be matched as needed | 0.05mm to 0.15mm |

| Anodized | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

| E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

| Nickel Plating | Metal | Gloss | Silver | 0.004mm to 0.05mm |

| Chromed | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

| Zinc Plating | Metals | Gloss | Silver & Black | 0.005mm to 0.2mm |

| Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 μm |

インスタント引用とカスタマイズされたソリューションを取得します

以下のフォームに詳細と問い合わせをご記入ください。私たちの代表者の一人がまもなくあなたに戻ってきます。