低容量の部品で市場をすばやくテストする必要がありますか?または、大量の生産部品を作成したいですか?そうすれば、プラスチックの射出成形サービスを間違えることはありません。 ENQIでは、アルミニウム型から高品質のプロトタイプモールディングを生成し、速い回転時間を速い時間にします。お客様は、製造可能性、機能性、マーケティングについて設計を迅速にテストできます。また、大量の生産ニーズに合わせてプラスチック射出成形を提供します。

2k+

顧客

提供

29+

国

提供

1m+

部品

作った

15+

年

ビジネスで

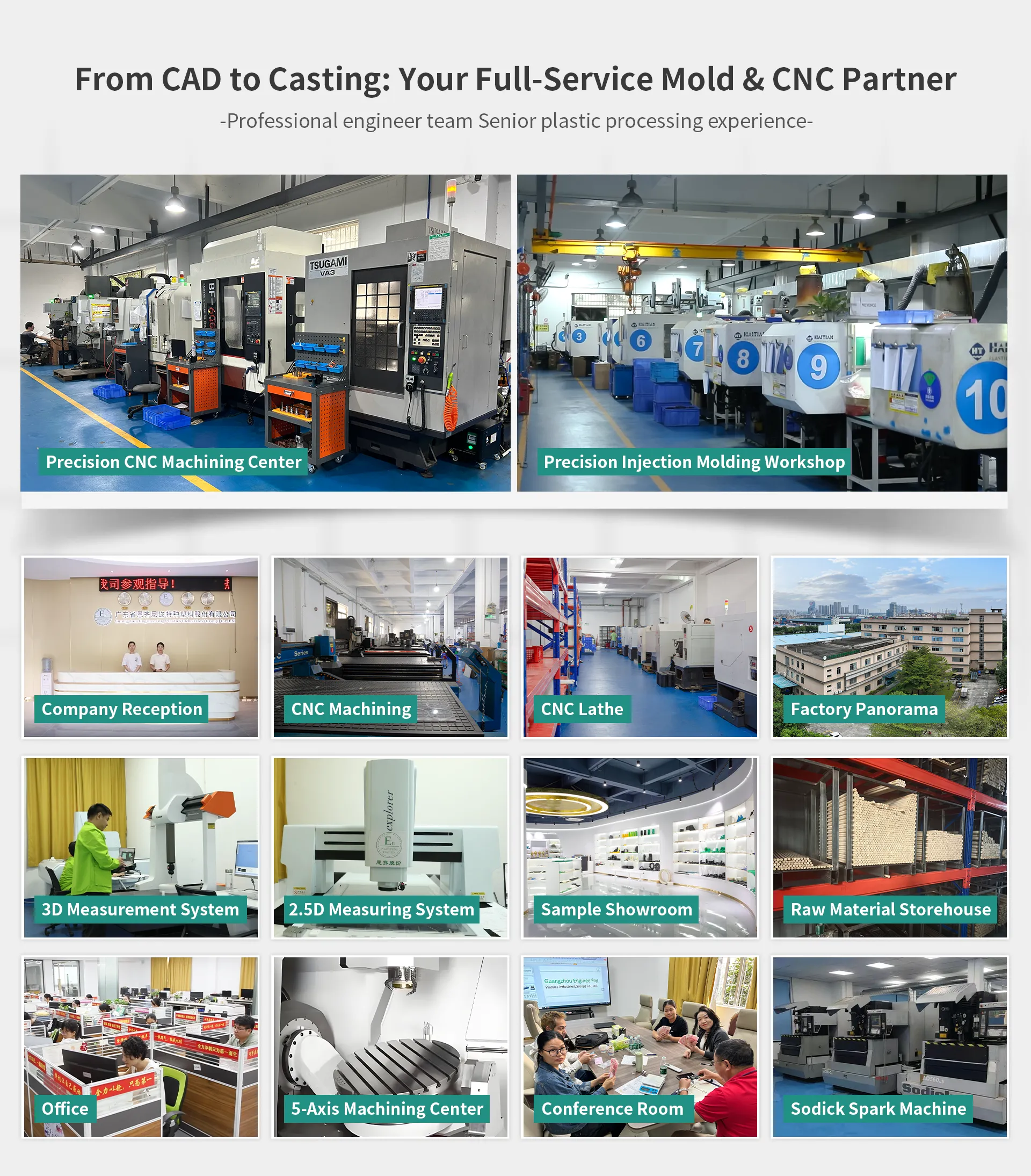

ENQIがプラスチック射出成形の最良の選択肢である理由

顧客向けに成形されたプラスチック部品を作成する長年の経験により、ENQIは他の企業よりも多くの利点を提供します。デザインから生産まで、真にエンドツーエンドのプラスチック射出成形サービスを提供し、常に最高の品質を保証しています。

ENQIがプラスチック射出成形の最良の選択肢である4つの理由を以下に示します。これは、スケールが何であれ、どのような部品でもありません。

金型作り

カビ製造と射出成形の両方を処理できます。つまり、部品の製造を端から端まで監督し、必要に応じて生産を簡単に拡大できることを意味します。

数量のロックを解除します

ほとんどのプラスチック射出成形会社は、大量生産に焦点を当てています。しかし、私たちはより柔軟で、低量のプロトタイピング、1m+部品の大量生産、およびその間のすべてを提供します。

信頼できる品質

私たちの経験豊富なエンジニアは、あなたの部品に最適な射出成形パラメーターを決定するのを手伝う前に、専門家のDFM分析と金型作成でプロジェクトをキックスタートできます。

無制限の容量

社内の施設に加えて、大規模なプラスチック射出成形メーカーネットワークと提携しています。注入機の艦隊は今日あなたの注文の準備ができています。

追加のプラスチック射出成形オプション

オーバーモールディング

オーバーモールディングは、プラスチック射出成形会社が複数の材料から部品を作成するカスタムプラスチック射出成形の一種です。このプロセスは、既存の射出成形ワークピースに射出成形材料層を追加し、複数の材料で作られた化学的に結合した部品を生成します。

オーバーモールディングプロセスを使用して、層状の部品をゼロから構築するか、既存のプラスチック部品とツールに耐性の外層を追加して、より頑丈な外装を提供します。固体のプラスチックボディとゴム製グリップで構成される歯ブラシは、オーバーモールド製品の一般的な例です。

成形を挿入します

挿入成形はオーバーモールディングに似ていますが、基質は必ずしもプラスチックではなく、射出成形を介して生成する必要はありません。たとえば、挿入成形を使用して、プラスチックコーティングをブレードやねじ付きインサートなどの事前に製造された金属部品に追加できます。

インサートモールディングで作られた一般的な部品には、プラスチックハンドル内に部分的に収容された金属製の刃で構成されるメスなどの鋭いハンドヘルドツールが含まれます。挿入成形は、ブッシング、クリップ、ファスナーを組み込んだ製品を作成するために頻繁に使用されます。

プロトタイプモールディングと大量生産モールディング

4つの簡単なステップで高速で配信されます

CADファイルをアップロードします

引用を要求するときに、3Dモデルをアップロードするだけで、技術的な図面、優先資材、および仕上げ要件があります。そこから取ります。

ご注文を確認してください

お客様のリクエストを評価し、DFM分析を実行し、見積もりを提供します。条件に満足している場合は、すぐにプラスチックの射出成形プロジェクトを開始できます。

生産

経験豊富なエンジニアのチームは、1回限りのプロトタイプであろうとより大きな注文であろうと、カスタムプラスチックの射出成形を迅速に行います。

配達

私たちはあなたの射出成形されたプラスチック部品を世界中のどこにでも出荷します。たとえそれが多くのユニットの大量注文であっても、あなたはあなたの貨物を迅速に取得します。

射出成形材料

産業用グレードの多様な材料が成形部品に利用でき、プロトタイプと生産の両方に大きな柔軟性を提供します。材料には、ABS、PC、PP、PAなどの一般的なプラスチックと、PEIやPPSなどの高性能で耐性のあるオプションが含まれます。マテリアルガイドページで、マテリアル選択のヒントと推奨事項の詳細をご覧ください。

ABS

ABS(アクリロニトリルブタジエンスチレン)は、その強度、耐久性、および処理の容易さで知られている汎用性のある熱可塑性ポリマーです。自動車部品、家電、医療機器などのアプリケーションで広く使用されています。

射出成形プラスチック

当社のプラスチック射出成形サービスは、さまざまな成形材料の部品の製造をサポートしています。これらには、ABSのような剛性プラスチック、TPEなどの柔軟なプラスチック、PC-ABなどの混合素材が含まれます。また、専門材料を入手し、注文に合わせてカスタム材料と顔料ブレンドを作成することもできます。

リジッドプラスチック

射出成形部品の大部分は、硬質熱可塑性形成から作られています。これらには、ABSやPPなどの安価で多用途のプラスチック、PCやアクリルなどの自然に透明なプラスチック、POMのような高強度のプラスチックが含まれます。射出成形用の他の硬質プラスチックには、ナイロン、ペット、PSが含まれます。

プラスチック射出成形仕上げ

表面仕上げをモールディングに適用する最も便利な方法は、金属型で必要な仕上げを実行することです。このようにして、マット、ハイグロス、さまざまなテクスチャなど、モールディングにさまざまな表面仕上げを与えることができます。完成したモールディングに適用される二次仕上げもオプションです。

マット

ENQIのようなプラスチック射出成形会社は、サンドブラスト、化学エッチング、EDMなどの技術を金属型で実施することにより、プラスチック射出成形部品(ソフトグリップハンドルなど)に一貫したマット仕上げを与えることができます。マットモールディングの表面粗さは通常、0.40〜18.00 RA µmの範囲です。

プラスチック射出成形の詳細をご覧ください

プラスチック射出成形とは何ですか

プラスチック射出成形は、主に大量のプラスチック部品を作るために使用される製造プロセスです。多くの産業で多種多様な部品に使用されるプラスチック射出成形は、他のどのプラスチック製造プロセスよりも年間熱可塑性部品をより多く生成します。 プラスチック注入プロセスには、金属型と射出成形機が必要です。プラスチックペレットは融点まで加熱され、その後、カビの形状を想定して、材料が冷えて固化する金型に強制されます。 プラスチック射出成形の最も一般的な材料は、ABS、ナイロン、アクリルなどの熱可塑性プラスチックです。ただし、熱硬化性とエラストマーを成形することも可能です。 プラスチックの射出成形は、ボトルキャップから大きな自動車パネルまで、さまざまなサイズの部品を生成できますが、型プラスチックの厚いセクションは金型内で冷却すると変形する可能性が高いため、薄壁の部品に最適です。

品質管理

ENQI Manufacturingでは、品質が最優先事項です。製造プロセス全体に厳密な品質管理措置を実施して、すべての部品が最高水準の精度と信頼性を満たすことを保証します。当社の包括的な品質保証システムには、当社の製品の一貫性と卓越性を維持するための高度な検査ツールと技術が含まれています。

インプロセス検査

当社の品質管理は、設計仕様の順守を確保するために、各部品が生産のさまざまな段階でチェックされるプロセス内検査から始まります。この積極的なアプローチは、製造プロセスの早い段階で問題を特定して修正するのに役立ちます。

最終検査

任意の部品が施設を離れる前に、その品質と精度を確認するために、徹底的な最終検査を受けます。高度な測定ツールとテクニックを使用して、各部品が必要な仕様と標準を満たしていることを確認します。

精密測定ツール

CNC機械加工部品の寸法と公差を正確に測定するために、座標測定機(CMM)、光学コンパレータ、レーザースキャナーなど、さまざまな精度測定ツールを利用します。これらのツールにより、私たちが生成するすべてのコンポーネントで緊密な許容範囲と高精度を維持することができます。

ISO 9001、ISO 14001、IATF 16949およびAS9100D認証

品質へのコミットメントは、ISO 9001、ISO 14001、IATF 16949、およびAS9100D認定によって実証されています。この国際標準により、当社の品質管理システムが効果的かつ継続的に改善され、顧客に一貫した高品質の製品を提供します。

継続的な改善

私たちは継続的な改善を信じており、プロセスと実践を定期的にレビューして、強化の領域を特定します。スタッフのための最新のテクノロジーとトレーニングに投資することで、品質と革新に対する評判を維持するよう努めています。

業界アプリケーション

あなたのプロジェクトの助けが必要ですか?

プロジェクトのサポートが必要な場合は、お問い合わせください。