Online Custom CNC

Milling Services

As a precision parts manufacturer, Enqi provides on-demand

CNC milling services. Contact us and get your quote today!

- One-Off CNC Prototypes

- 100K+ Mass Production Machining

- Tolerance as Tight as ±0.01 mm

- ■Response within 10 hours

- ■Secure file upload

- ■Delivery in as fast as 5 days

Our CNC Milling Services

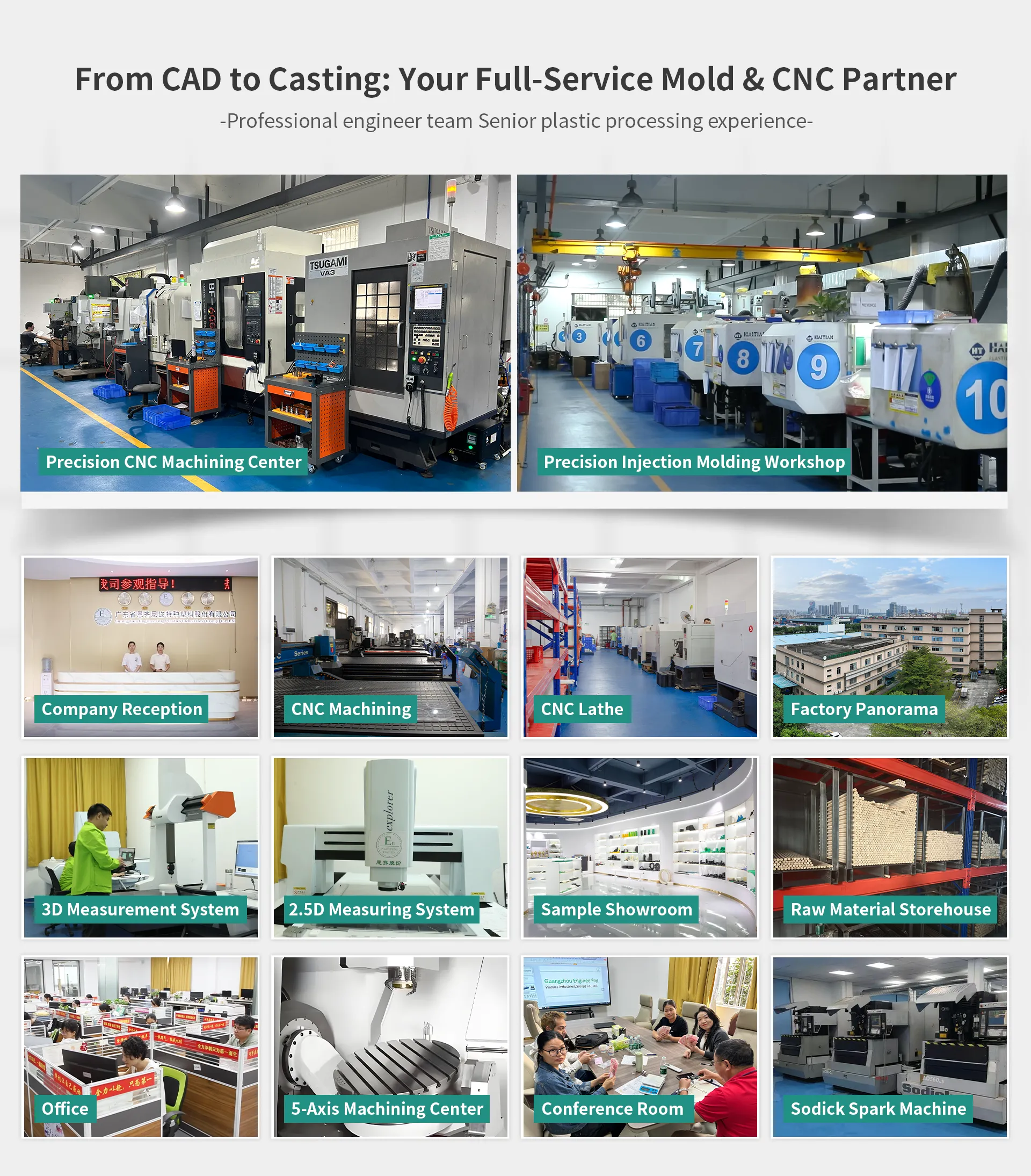

EnQi, an ISO 9001:2015 certified manufacturer, offers custom CNC milling services with rapid lead times and precision results.

With two milling shops, including 3-, 4-, and 5-axis machines, we manufacture tight-tolerance parts in both metals and plastics.

Trusted by startups and global manufacturers alike, EnQi is your dependable CNC machining partner. Whether you're prototyping a new design or scaling up to full production, EnQi ensures precision, consistency, and quick turnaround. Request your custom quote today.

Why Choose EnQi?

Advanced CNC Milling Machines

EnQi operates two CNC milling shops equipped with over 50 machines. Your machined parts can be completed in as little as 5 days, with no delays. We also offer machining services from CNC shops near your location in the US and Europe, reducing shipping time.

Rapid Turnaround From Prototype To Production

EnQi specializes in rapid CNC milling services, ensuring a quick turnaround from prototype to production. We deliver high-quality parts quickly and efficiently by utilizing our advanced facilities and trusted manufacturing network. Whether you need a single prototype or a large production run, we meet your desire without compromising on quality.

Experienced CNC Engineers And Machinist

With over 15 years of experience, our skilled CNC engineers and machinists work seamlessly together to ensure clear and efficient communication at every stage. Whether adjusting designs, answering questions, or optimizing processes, we are dedicated to delivering the best results.

Efficiency And Cost-Effective CNC Solutions

At EnQi, we specialize in optimizing precision processing programs to minimize waste, improve cycle times, and reduce production costs. This approach accelerates timelines, saves materials and labor, and delivers cost-effective solutions without compromising quality.

CNC Milling Processes for Custom Parts

Our precision CNC multi-axis milling transforms your designs from concept to reality, ensuring exceptional accuracy and craftsmanship every time.

3-Axis CNC Milling Service

3-Axis CNC milling is the most cost-effective way to get simple CNC prototypes and production parts done with accuracy demands.

4-Axis CNC Milling Service

Besides less set-up compared with 3-axis milling, 4-axis milling is an exclusive option for the long parts with features on the side wall.

5-Axis CNC Milling Service

5-Axis CNC milling is the best solution for complex precision parts. The workpieces can be milled from multiple directions.

CNC Machining Materials

PEEK

A high-performance, heat-resistant plastic with excellent chemical resistance, commonly used in aerospace, medical, and automotive parts.

Tolerances

At EnQi, we offer a comprehensive range of materials for CNC milling to meet diverse application needs. Our material options are carefully selected to ensure the best performance, durability, and precision for your specific project requirements.

Feature

Description

Maximum Part Size

4000×1500×600 mm

Distance Dimensions

For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005"

Orientation and Form Dimensions

0-12" +/- 0.005", Angularity 1/2 degree. For 24" and beyond please consult EnQi's Manufacturing Standards.

Precision Tolerances

EnQi can manufacture and inspect to tight tolerances, including sub +/- 0.001" tolerances, per your drawing specifications and GD&T callouts.

Minimum Feature Size

5 x 5 x 5 mm

Threads and Tapped Holes

EnQi can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

Surface Finish

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote.

Edge Condition

Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print.

Need Assistance? We're Here for You.

If you have any questions or need assistance, our team is ready to provide support 24/7. Reach out to us through any of the methods below.