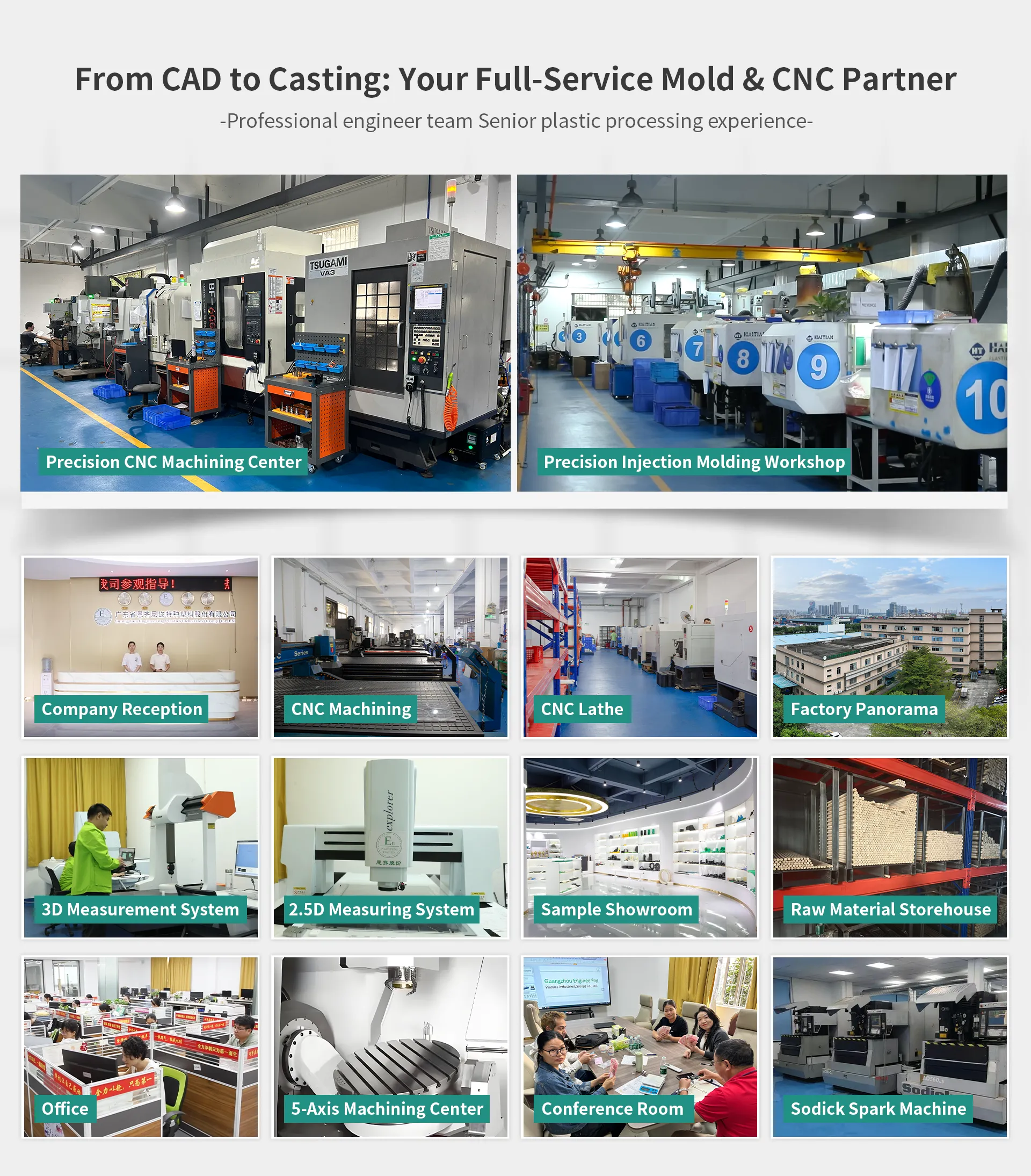

Why manufactureindustrial machinery partswith EN?

ISO certified

Guangdong Enineering Pastics induties (Group) Co. Ltd.is an lS09001-2015 certified manufacturerthat can guaran-tee top quality parts in an industrythat demands rigorousconsistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size, from one-off engine part prototypes to full production of injection molded headlamp covers.

Range of services

Equal parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Short lead time

Our extensive facilities and partner network allow us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

We have been manufacturing aerospace parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Industrial machinery prototyping with EN

Guangdong Engineering Plastics company are applicable throughout the industrial equipment industry. Visualizing how a given prototype is likely to perform in the real application environment is a critical phase during any product design process.

We subject our prototypes to stress and strain tests, and this ensures that we can eliminate any factor that might introduce failure in the systems we develop.

What kind ofindustrialmachinery partscan we make?

Industrial machinerymanufacturingprocesses

We offers wide range of manufacturing processes for industrial machinery prototypes and production parts.

View all services →

Mold Making

From concept to production, our custom molds ensure tight tolerances, material durability, and cost-efficiency.

Injection Molding

We offer low-volume prototype moldings and mass production moldings.

CNC Machining

By using CNC milling & turning, we can make a wide range of prototypes and production parts.

Engineering Plastics

Tailored formulations and precision processing ensure optimal material performance.

IndustrialmachineryPart Gallery

For the years we have gathered relevant experience that enables us to handle any industrial projects. Here's the gallery of industrial machinery prototypes and production parts for our worldwide clients.

Get Instant Quote →

Industrial machinery manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for industrial machinery are listed below.

| Best technologies | Manufacturing methods | Benefits | Example parts |

|---|---|---|---|

| CNC machining,injection molding | Lightweight,ideal for extreme conditions | Insulating connectors,semiconductor carriers |

| CNC machining,injection molding | Cost-effective,versatile design | Pipes,protective casings,housings |

| CNC machining,injection molding | High stiffness,low friction,wear resistance | Bearings,pulleys,valves,gears,guide |

| CNC machining, SLS 3D printing, injection molding | Strong, smooth surface finish | Peripheral engine parts, covers and housings |

| CNC machining, injection molding | Transparent, shatter-resistant | Lighting components |

| Liquid silicone injection molding | Durable, flexible, biocompatible, inert | Seals, cover assemblies, Fluid management devices, respiratory devices |

Surface Treatment Methods

We offer a variety of surface treatment methods to meet different industrial application requirements

| Name | Applicable to | Feature | Color | Thickness |

|---|---|---|---|---|

| As machined | Metals & Plastics | Tool marks visible | N/A | N/A |

| Sanding & Polishing | Metals & Plastics | Brushed & gloss mirror surface | N/A | 0.02-0.05mm removed |

| Sand, Bead Blasted | Metals & Plastics | matt or satin surface | N/A | N/A |

| Painted | Metals & Plastics | Matt, gloss, texture | colors can be matched as needed | 0.05mm to 0.1mm |

| Powder coat | Metals | Matt, Gloss & Texture | colors can be matched as needed | 0.05mm to 0.15mm |

| Anodized | Aluminum | Tool marks visible, Smooth, Matt & Gloss | colors can be matched as needed | 0.002mm to 0.04mm |

| E-Coating | Metals | Matt & Gloss | Black | 0.015mm to 0.035mm |

| Nickel Plating | Metal | Gloss | Silver | 0.004mm to 0.05mm |

| Chromed | Metals & Plastics | Satin & Gloss | Silver | 0.001mm to 0.3mm |

| Zinc Plating | Metals | Gloss | Silver & Black | 0.005mm to 0.2mm |

| Chromate Conversion Coating | Aluminum | Tool marks visible, Smooth and Matt | Clear/ slight yellow tint | 0.25-1 μm |

Get Instant Quote And Tailored Solution

Please fill out the form below with your details and inquiry. One of our representatives will get back to you shortly.