CNC Turning with EnQi

EnQi CNC turning process produces metal and plastic turned parts in days. We are an ISO 9001:2015 certified manufacturer offering high-quality custom CNC turning services to clients worldwide. With over 20 years of experience, our CNC turning capabilities allow us to deliver turned parts with consistent quality.

As a leading turned part supplier, we support custom projects from prototypes to full-scale production. Our precision CNC turning lathes are capable of producing both simple and complex cylindrical geometries with tight tolerances. Our CNC lathes with live tooling can machine features like axial/radial holes, grooves, slots, and flats, with high repeatability, even for tight-tolerance geometries.

Whether you're a startup launching a first product or a global manufacturer needing a reliable partner, EnQi delivers expert engineering, fast turnaround, and competitive pricing for your CNC turning projects.

Why Choose EnQi?

Advanced CNC Turning Capabilities

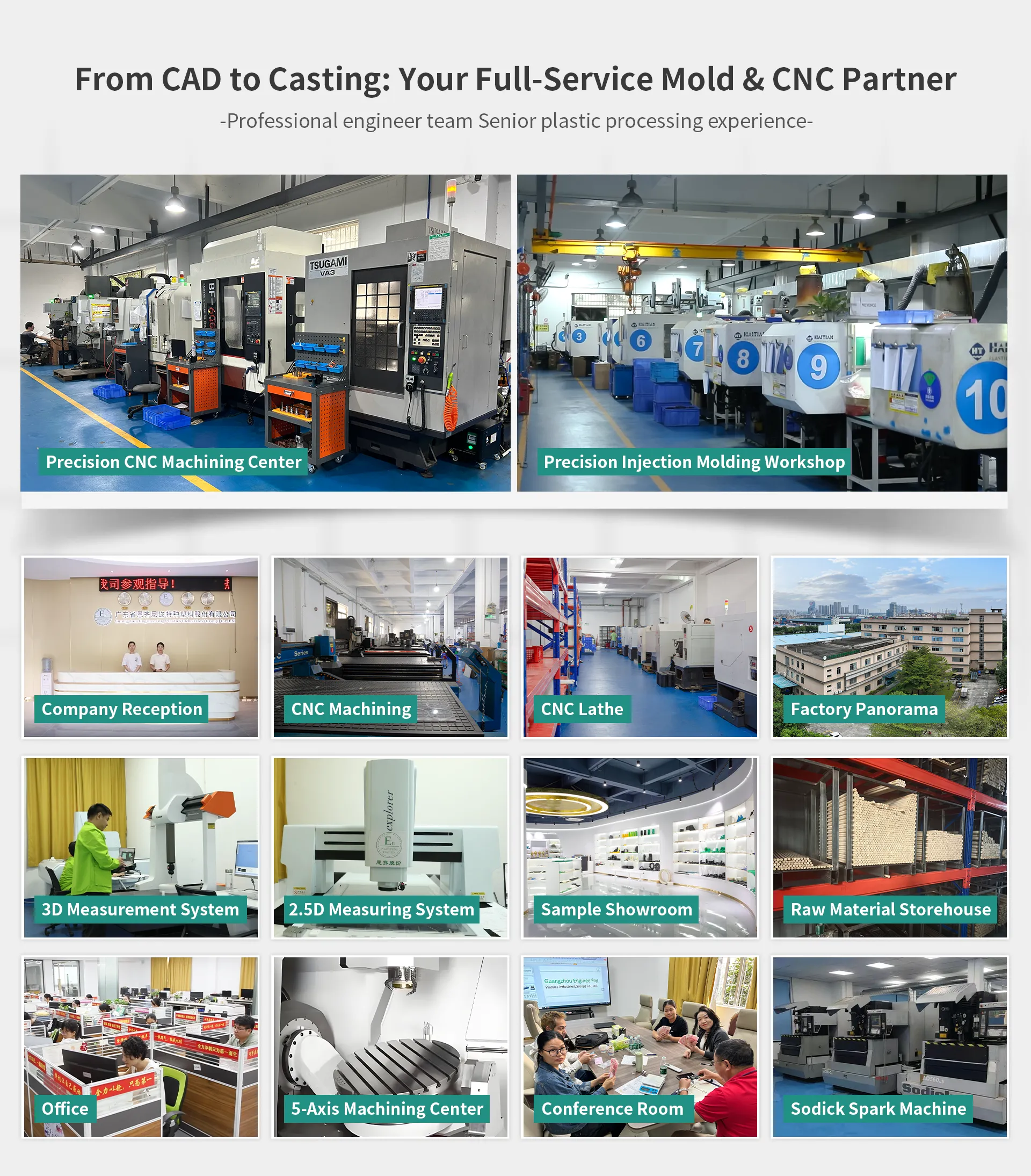

EnQi operates two CNC machining facilities, equipped with over 60 machines, including advanced multi-axis CNC lathes. Custom turned parts can be manufactured in as little as 5 days, helping you avoid production delays and stay ahead of schedule.

End-to-End CNC Turning Solutions

From functional prototypes to low-volume production, we bridge the gap between design and delivery. Our integrated CNC turning manufacturing systems accelerate product development while maintaining tight tolerances and consistent part quality across every production stage.

Experienced CNC Engineers

Our expert team specializes in CNC turning services with deep knowledge of DFM validation, material selection, and achieving complex geometries. We support you through every phase—from drawing and part analysis to precision CNC turning—ensuring smooth communication.

Mastering Complex CNC Turning Projects

Our CNC lathes can produce complex cylindrical components such as stepped shafts, bushings, collars, housings, and other custom-designed round parts. We machine both metals and engineering plastics, delivering high dimensional accuracy, fine surface finishes, and excellent concentricity.

CNC Turning Materials

Our CNC turning services support a wide range of metals and engineering plastics. Whether you need precision turning of plastic parts or other materials, we can deliver precise parts or industries such as automotive, aerospace, and medical devices. If your project requires a specific material, feel free to contact us- -our team will evaluate your requirements and recommend the best solution.

PEEK

航空宇宙、医療、および自動車部品で一般的に使用される優れた耐薬品性を備えた高性能の熱耐性プラスチック。

CNC Turning Tolerances

We deliver CNC turned parts with both standard (±0.1mm) and tight tolerances (±0.005mm), balancing cost efficiency with high precision. Whether for general applications or advanced products, our CNC turning services guarantee every component meets your exact specifications.

Feature

Description

Maximum Part Size

4000×1500×600 mm

Distance Dimensions

For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005"

Orientation and Form Dimensions

0-12" +/- 0.005", Angularity 1/2 degree. For 24" and beyond please consult EnQi's Manufacturing Standards.

Precision Tolerances

EnQi can manufacture and inspect to tight tolerances, including sub +/- 0.001" tolerances, per your drawing specifications and GD&T callouts.

Minimum Feature Size

5 x 5 x 5 mm

Threads and Tapped Holes

EnQi can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

Surface Finish

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote.

Edge Condition

Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print.

品質管理

ENQI Manufacturingでは、品質が最優先事項です。製造プロセス全体に厳密な品質管理措置を実施して、すべての部品が最高水準の精度と信頼性を満たすことを保証します。当社の包括的な品質保証システムには、当社の製品の一貫性と卓越性を維持するための高度な検査ツールと技術が含まれています。

インプロセス検査

当社の品質管理は、設計仕様の順守を確保するために、各部品が生産のさまざまな段階でチェックされるプロセス内検査から始まります。この積極的なアプローチは、製造プロセスの早い段階で問題を特定して修正するのに役立ちます。

最終検査

任意の部品が施設を離れる前に、その品質と精度を確認するために、徹底的な最終検査を受けます。高度な測定ツールとテクニックを使用して、各部品が必要な仕様と標準を満たしていることを確認します。

精密測定ツール

CNC機械加工部品の寸法と公差を正確に測定するために、座標測定機(CMM)、光学コンパレータ、レーザースキャナーなど、さまざまな精度測定ツールを利用します。これらのツールにより、私たちが生成するすべてのコンポーネントで緊密な許容範囲と高精度を維持することができます。

ISO 9001、ISO 14001、IATF 16949およびAS9100D認証

品質へのコミットメントは、ISO 9001、ISO 14001、IATF 16949、およびAS9100D認定によって実証されています。この国際標準により、当社の品質管理システムが効果的かつ継続的に改善され、顧客に一貫した高品質の製品を提供します。

継続的な改善

私たちは継続的な改善を信じており、プロセスと実践を定期的にレビューして、強化の領域を特定します。スタッフのための最新のテクノロジーとトレーニングに投資することで、品質と革新に対する評判を維持するよう努めています。

カスタマーレビュー

革新的な企業から信頼されています

業界アプリケーション

支援が必要ですか? 私たちはあなたのためにここにいます。

ご質問がある場合や支援が必要な場合は、チームがサポートを提供する準備ができています 24/7。以下のいずれかの方法を通して私たちに連絡してください。