Understand ABS plastic shell

ABS plastic shells are becoming increasingly popular in various industries due to their durability and versatility. ABS stands for acrylonitrile butadiene styrene, a thermoplastic polymer known for its strength and elasticity under different conditions. This material is ideal for manufacturing shells because it combines mechanical toughness with excellent surface quality and is easy to mechanize, making it suitable for complex designs.

ABS plastic housing is often used in the automotive industry, equipment manufacturing and electronics because of its resistance to impact and excellent electrical insulation properties. Its ability to withstand high temperatures without deformation makes it a reliable choice for parts that are subject to heat. By using a professional ABS case, the company can ensure that its products are protected while also maintaining a sleek appearance.

Advantages of professional ABS houses

Professional ABS shells have many advantages over traditional materials. First, they provide superior protection for external damage. ABS plastics are scratch-resistant and rust-resistant to ensure that the house remains intact and performs best in the long term. These shells are lightweight but robust, perfect for portable devices or weight components.

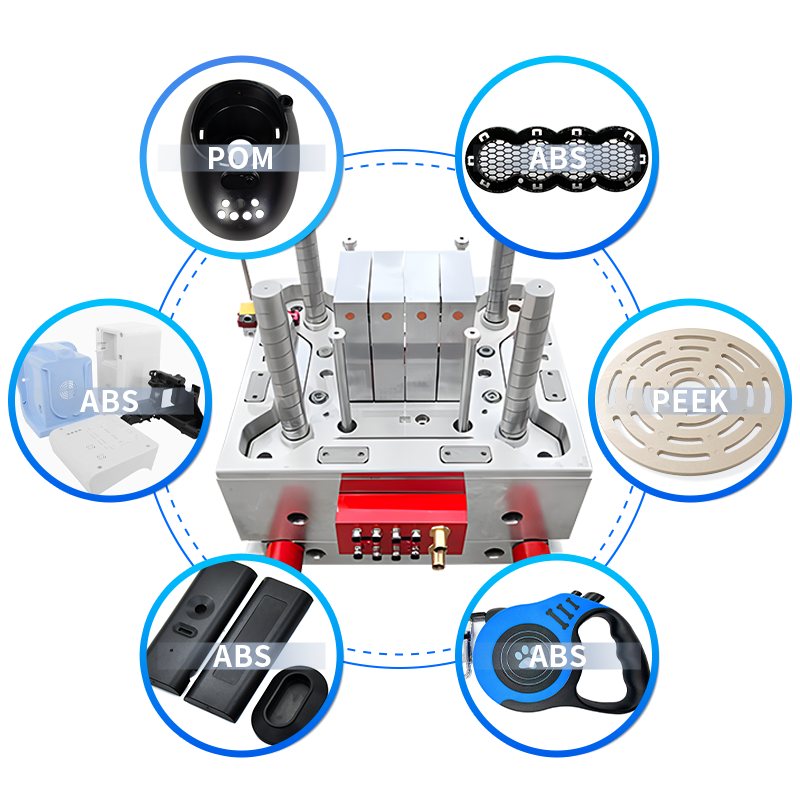

Manufacturers generally prefer professional ABS case because of their flexibility in design and customization. With ABS plastic housing molds, it is easy to mold materials into various shapes and sizes to innovate in product design. Whether it is complex patterns or smooth finishes, the adaptability of ABS plastic shells ensures that the product meets high standards. Furthermore, its ease of tinting and finishing means that products can be tailored to specific aesthetic requirements.

Application and future trends of ABS plastic shell

ABS plastic housing is widely used in a variety of fields from electronics to industrial applications, highlighting its importance in modern manufacturing. The electronics industry benefits greatly from ABS homes because they provide excellent shelter for sensitive components. With the demand for durable and stylish electronics, the use of ABS plastics is expected to grow significantly.

Looking at the future, advances in ABS plastic shell technology will lead to more innovative designs and uses. Companies and designers have been exploring new ways to leverage this versatile material, resulting in exciting developments in product design and efficiency. As sustainability becomes a priority, ABS plastic shells remain a preferred material due to their recyclability, paving the way for more environmentally friendly products.

In short, ABS plastic shells are a key component in modern production processes and consumer products. Its durability, flexibility and customizable capabilities make it a higher choice for manufacturers. By adopting advanced molding technology, the industry can leverage the full potential of ABS plastic shells to ensure the life and excellence of their products.

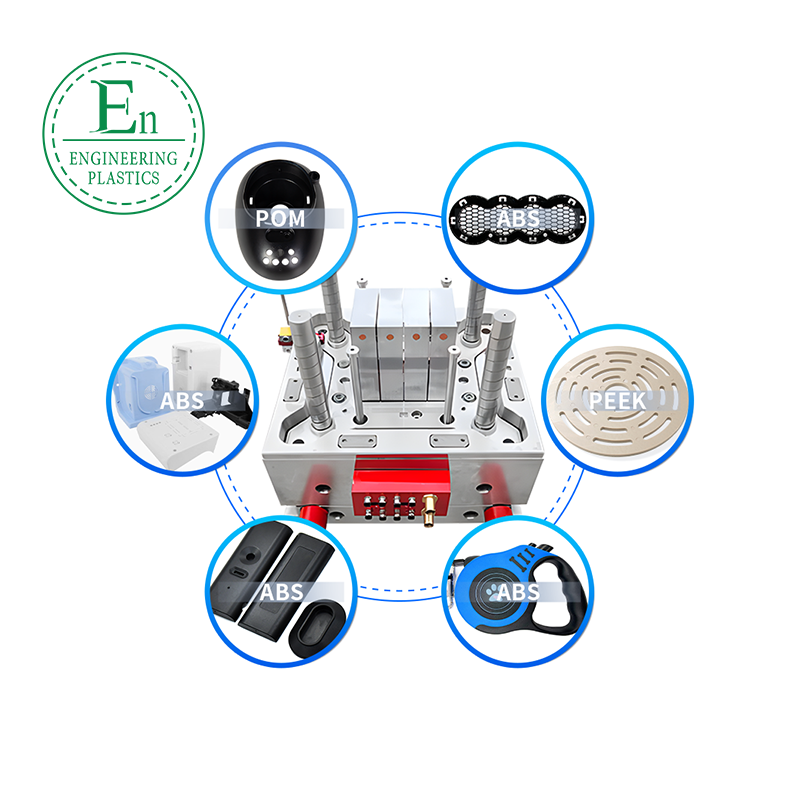

We are Guangdong Engineering Plastics Industry Group Co., Ltd. (Ltd.

Our expertise includes:

*Complex mold design: multi-cavity, hot runner and micro plastic functions

*Full-service production: from prototype production to mass manufacturing

*Material selection: engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001 certification has strict tolerance control (±0.01mm)

We have successfully provided projects for industries such as aerospace, automotive, robotics and medical equipment.

We can schedule a call to discuss how to optimize the quality, cost and lead time of your next project?

Email: sales@gz-plastics.com

Tel: +8618588927610

Website: https://gz-plastics.com/