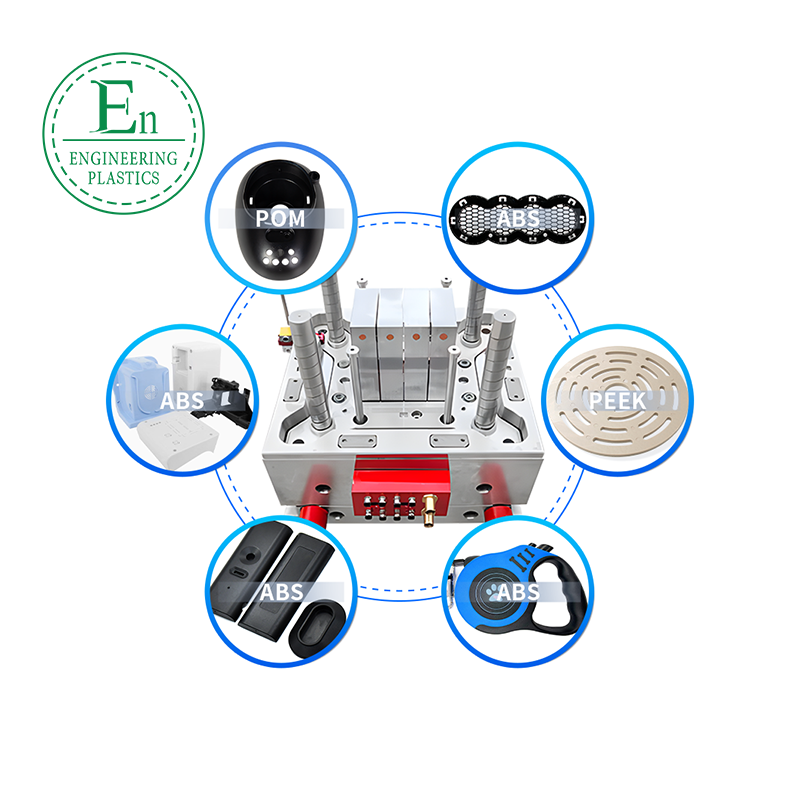

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

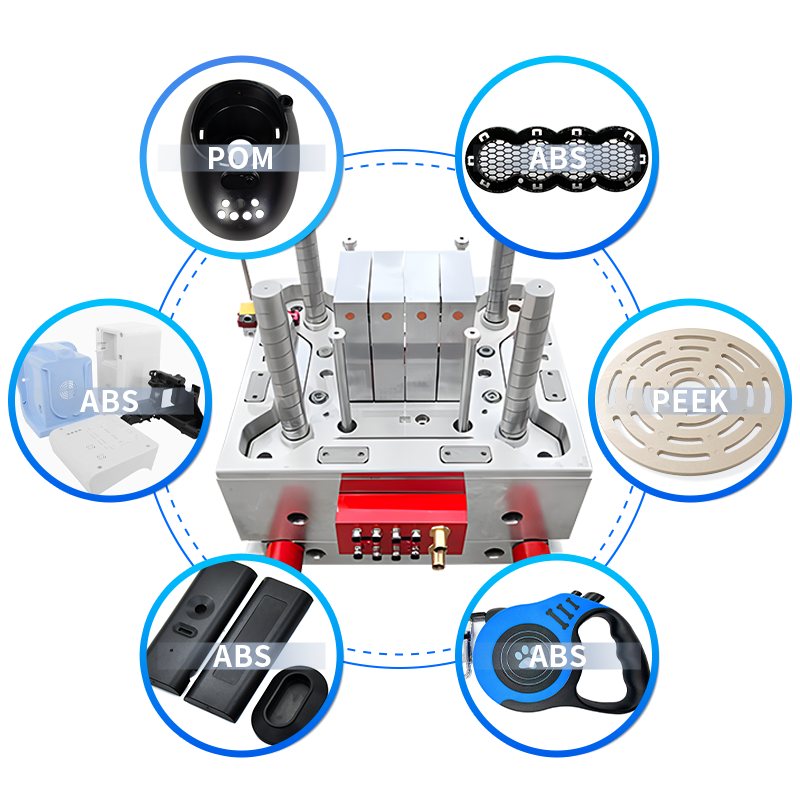

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Understanding the Role of a Mold Maker

Mold makers play a crucial role in manufacturing industries, crafting molds that serve as the foundation for creating a wide range of products. From intricate precision mold maker tasks to large-scale molds for industrial applications, their expertise ensures the final product meets exact specifications. Whether in metal fabrication or plastic molding, skilled mold makers are indispensable for bringing high-quality designs to life.

Why Precision Mold Makers are Highly Valued

In an era where accuracy and perfection matter more than ever, precision mold makers have become highly sought after. These experts craft molds with unparalleled exactness, ensuring that every aspect of the product is flawless. Precision mold makers rely on advanced tools and techniques such as CNC machines, CAD software, and meticulous inspections to deliver molds that meet stringent industry standards. This level of dedication minimizes defects in products, making them integral to sectors like automotive, aerospace, and medical device manufacturing.

The Rise of Metal Mold Makers in Manufacturing

Metal mold makers have gained prominence due to their ability to create durable molds for businesses producing metal components. By utilizing materials like steel and aluminum, these professionals ensure that molds withstand high temperatures and pressures during production. Metal mold makers also excel in customization, shaping molds to meet specific requirements of industries like construction, electronics, and machinery. Their work directly influences the quality, strength, and longevity of the end products.

Key Skills Every Mold Maker Must Possess

The role of a mold maker is not merely about technical ability; it requires a broad skill set to address industry demands effectively. Key skills include precision machining, problem-solving, and familiarity with various materials. Understanding manufacturing processes and maintaining attention to detail are equally crucial. Being adaptable and staying updated with evolving technologies further enhances their proficiency, ensuring they meet both current and future demands.

Conclusion: Mold Makers, the Backbone of Modern Manufacturing

Whether it's the craftsmanship of a precision mold maker or the expertise of a metal mold maker, these professionals drive innovation and quality across industries. Their skills and dedication transform raw materials into functional molds, leading to the creation of countless products we use daily. As industries continue to evolve, mold makers remain at the heart of manufacturing, proving their importance in shaping the future.