Understanding the Problem with Traditional Manufacturing

Injection molding, particularly in the plastic industry, has become a cornerstone of manufacturing due to its efficiency and ability to produce complex shapes. However, the challenge many businesses face is the high initial cost of traditional manufacturing methods, which often become a hurdle for small to medium businesses. Traditional methods also lead to longer production times, which can impede the timely launch of new products.

The Solution: Injection Molding and Its Benefits

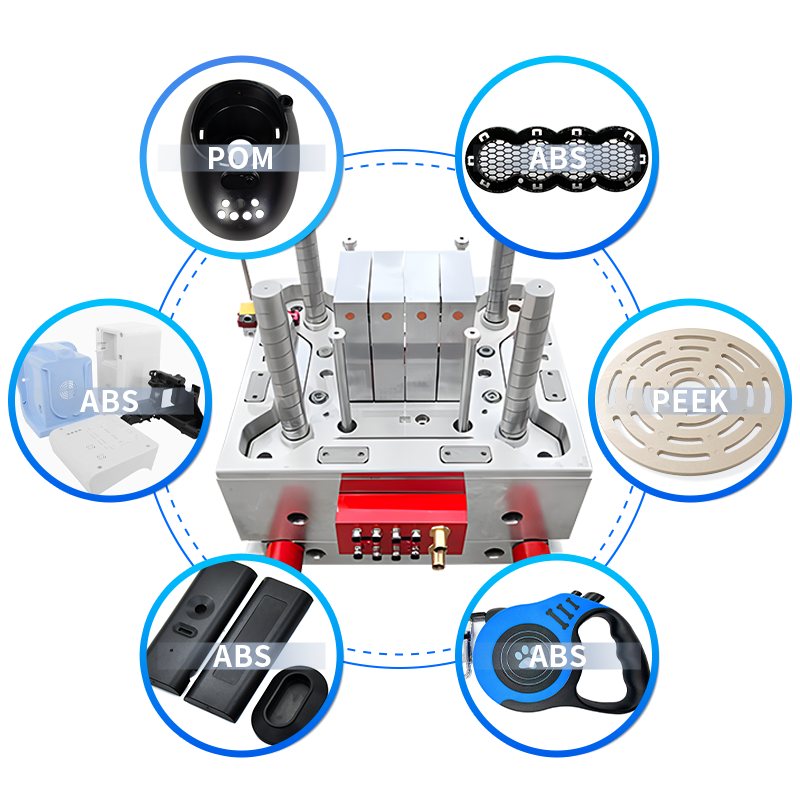

The injection molding process presents a powerful solution to these problems. By using an injection mold, manufacturers can produce parts in large volumes. This process is particularly efficient, reducing waste and saving time, thus lowering production costs over the long term. The versatility of injection molds allows for the creation of high-quality parts with intricate details, providing businesses with the flexibility to innovate their product designs. Moreover, plastic injection molding is compatible with a wide range of materials, enhancing product functionality and appeal.

Expert Tips for Implementing Plastic Injection Molding

To successfully integrate plastic injection molding into your manufacturing process, it is crucial to partner with experienced mold makers. These experts can guide you through designing molds that fit your specific product needs. It is also important to conduct thorough testing to ensure that your mold designs produce the desired quality and efficiency. By focusing on these aspects, you can leverage the full potential of injection molding, making it a cost-effective, high-quality solution for your manufacturing challenges. In conclusion, whether you are a small enterprise looking to scale or a larger company seeking to enhance production efficiency, injection molding offers a viable and robust solution to overcome traditional

manufacturing obstacles.

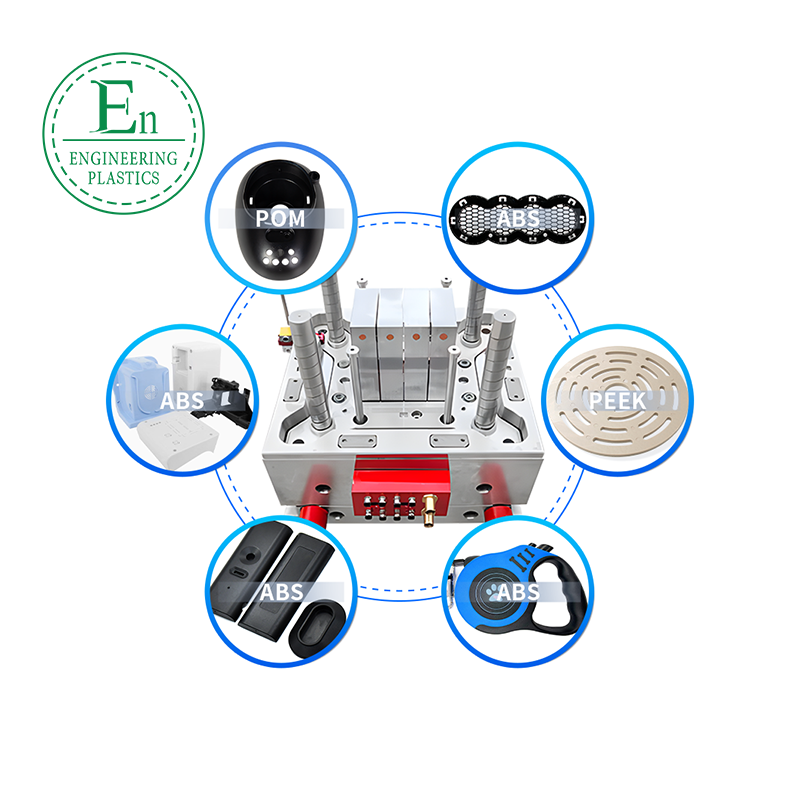

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/