Understanding ABS Plastic Injection

ABS plastic injection is a pivotal method in the realm of advanced manufacturing, enabling the creation of versatile, durable, and aesthetically appealing plastic components. This procedure harnesses the unique properties of Acrylonitrile Butadiene Styrene (ABS), a thermoplastic polymer known for its rigidity and toughness, to produce precisely engineered parts that meet diverse industry requirements. By integrating ABS plastic into injection molding processes, manufacturers achieve unparalleled precision in crafting high-grade components.

The Importance of ABS Injection Molding in Modern Industries

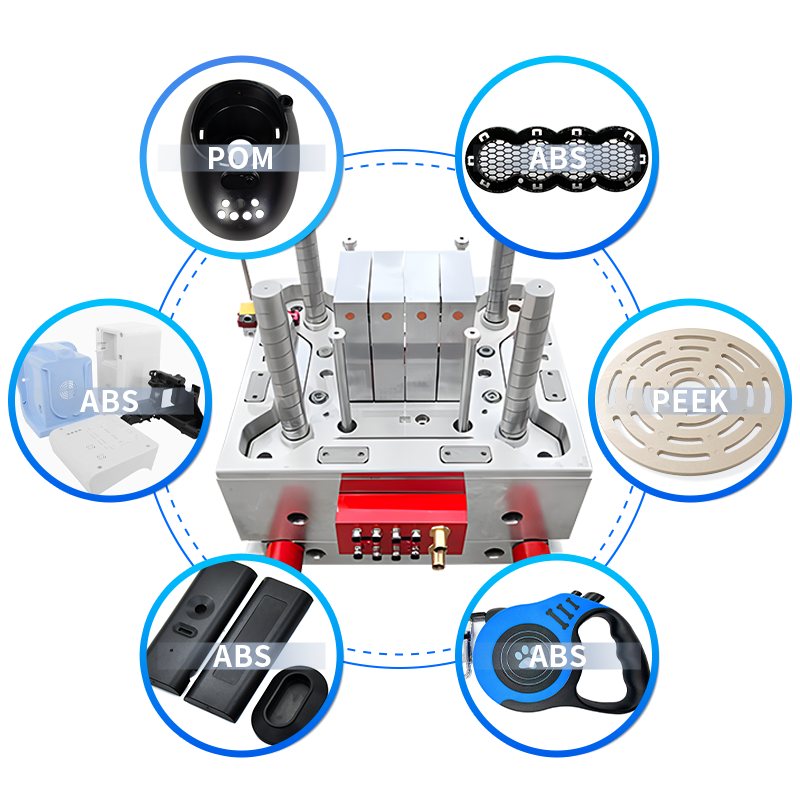

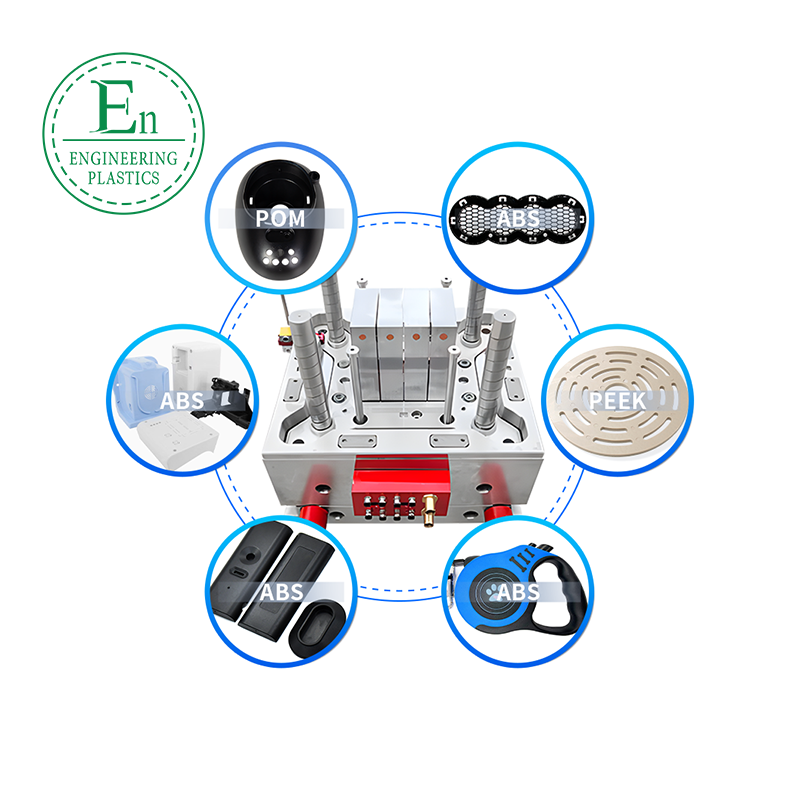

ABS injection molding serves as the backbone for manufacturing industries like automotive, electronics, healthcare, and consumer goods. The versatility of ABS polymer allows for a wide range of applications, from robust structural parts to lightweight and highly intricate designs. This capability is particularly evident in OEM/ODM custom-engineered plastic products, which elevate manufacturing standards by combining functionality, durability, and customization excellence.

In industries like automotive, ABS injection molding is utilized to produce sleek casings, ergonomic handles, and durable interior panels. In the medical sector, reinforced ABS plastic ensures reliable performance in casings for diagnostic equipment. The adaptability of ABS injection also shines in electronics, where intricate connectors, impact-resistant shells, and lightweight assemblies showcase the polymer's ability to meet demanding requirements efficiently. Whether embedding components into advanced machinery or upgrading devices, ABS injection molding makes industrial innovation seamless and achievable.

Technical Advantages of ABS Plastic and Material Quality

The technical superiority of ABS plastic is evident in its durability, thermal resistance, and mechanical robustness. These properties make it an ideal choice for creating molded parts that require strength and resilience. Components like gear systems, high-strength mechanical elements, and lightweight casings are crafted through ABS injection with detailed precision. Such materials ensure that products withstand harsh environments, thereby meeting both functional and aesthetic demands.

OEM/ODM plastic injection services further amplify the benefits of ABS injection molding by offering customization opportunities. From intricate mechanical designs to polished, sophisticated surfaces, the engineering ensures minimal compromise in quality or functionality. This approach aligns with sustainable manufacturing practices, helping modern industries achieve environmental goals without sacrificing efficiency or innovation.

How ABS Injection Redefines Manufacturing Excellence

ABS injection molding transforms industries with its customization capabilities and diverse applications. The ability to tailor-engineer plastic products for specific needs ensures that businesses can remain competitive while meeting consumer demand for quality and aesthetic appeal. Whether you are revolutionizing robotics, shaping modern automotive interiors, or producing reliable healthcare devices, ABS injection makes it possible to bring unique visions to life.

With trusted precision and dependability, ABS injection offers unparalleled versatility for businesses aiming to redefine innovation in manufacturing. Reliable durability, uncompromised detail, and sustainable efficiencies are just a few features that elevate ABS injection above conventional methods, paving the way for the future of engineered plastic manufacturing. ABS plastic injection is not only a process but a gateway to achieving exceptional product quality that supports creative and technical aspirations.