The demand for plastic molds in modern industries continues to grow

Plastic molds play a key role in a variety of industrial applications, from home products manufacturing to complex automotive parts. However, one of the biggest challenges facing businesses is finding reliable and cost-effective plastic mold manufacturers that can provide precision and efficiency. Chinese plastic manufacturers have become leaders in the field, providing innovative solutions, scalability and affordability.

Why choose a Chinese plastic mold manufacturer?

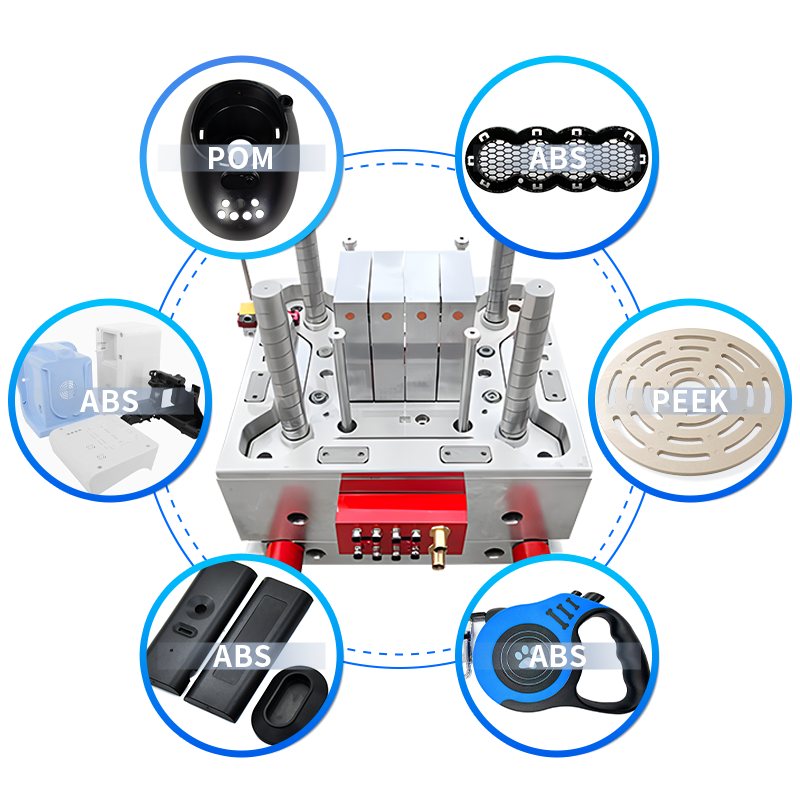

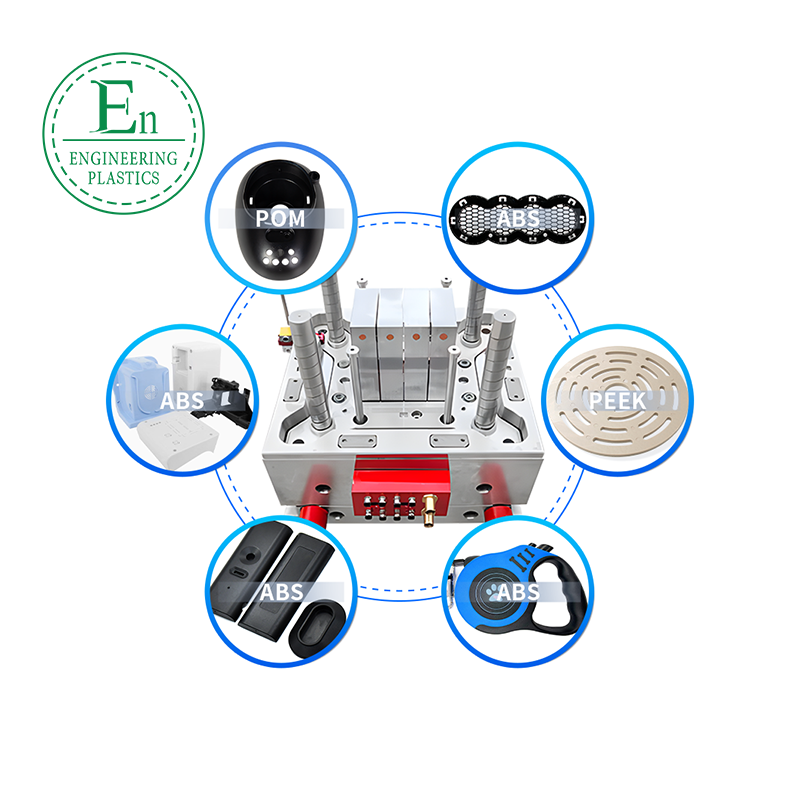

Due to its advanced technology, skilled labor and competitive pricing, many companies choose to work with plastic mold suppliers in China. These manufacturers have the ability to handle custom projects, which is a great choice for companies seeking custom plastic mold designs. Whether you are producing lightweight components for electronics or durable molds for industrial equipment, Chinese manufacturers are excellent in providing tailored solutions to meet quality standards.

In particular, their ability to adapt to unique specifications and their fast turnaround times help companies stay ahead of the competitive global market. In addition, China provides an ecosystem of experienced plastic mold suppliers that minimize logistics difficulties while maximizing production efficiency.

Challenges of finding the right manufacturer

Describing the ideal manufacturer can be daunting, despite the market being filled with many options. To avoid setbacks, such as late or unqualified products, companies must carefully evaluate potential suppliers. Key standards include technical capabilities, experience in producing customized plastics, and transparent pricing. Working with the most rated plastic mold suppliers in China will greatly reduce risks and promote overall project success.

How to ensure quality and reliability

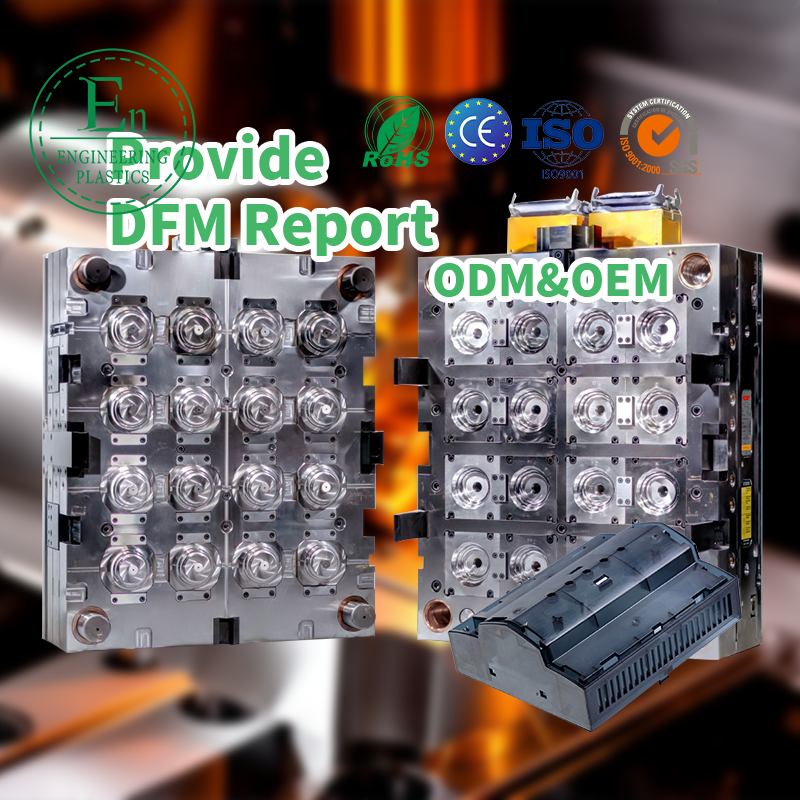

Selecting a custom plastic mold selection requires careful evaluation of manufacturing criteria. Whether you are researching injection molding or specialized tools, it is crucial to clearly communicate your requirements and ensure that manufacturers comply with international certifications (such as ISO standards). Performing quality inspections and requiring prototypes can help maintain high production integrity.

In short, Chinese plastic manufacturers have consolidated their reputation as a reliable partner in the global industry. By leveraging their expertise and infrastructure, companies can achieve cost-effective, high-quality production that meets growing market demand.