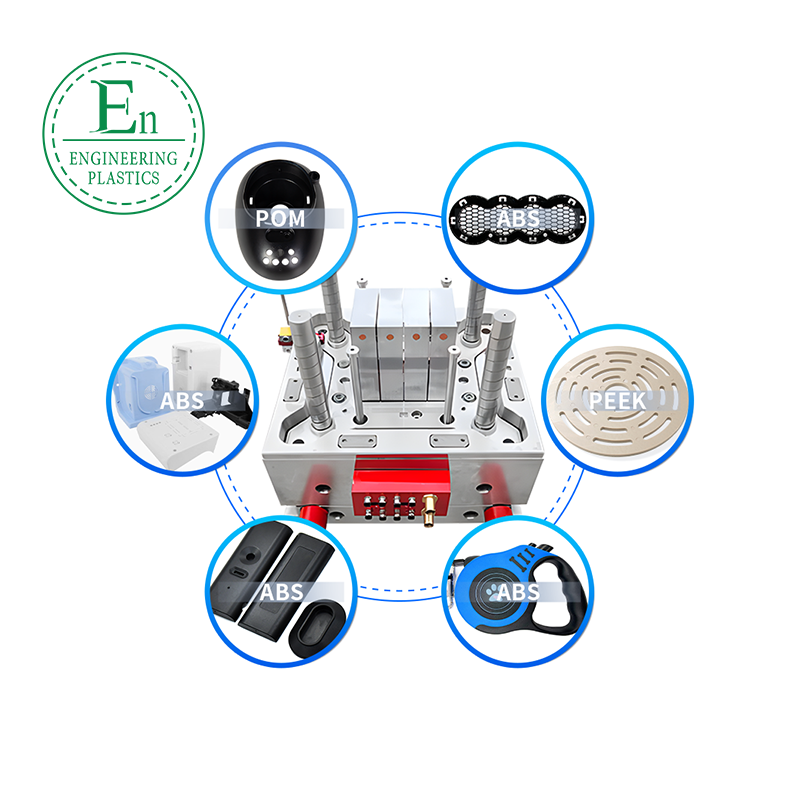

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

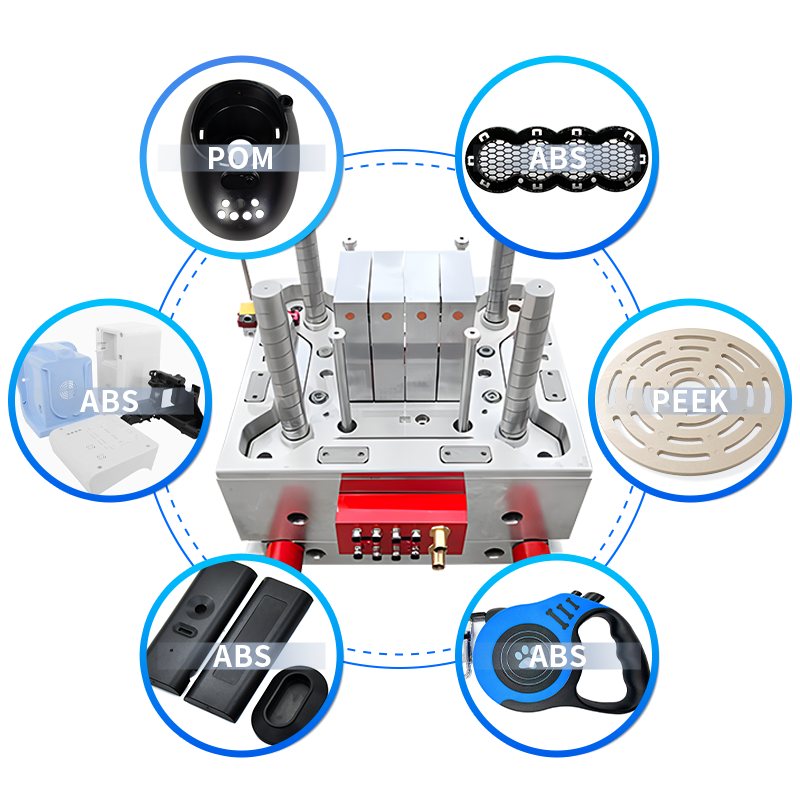

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Understanding ABS Mold Manufacturing

ABS mold manufacturing is a cornerstone of modern production processes, offering unparalleled precision and efficiency. ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its strength and durability, making it ideal for molding applications in various industries. The manufacturing process involves transforming client visions into reality by leveraging advanced technology and meticulous craftsmanship to create molds capable of producing high-quality components.

ABS mold manufacturing begins with a well-planned mold design, tailored to meet stringent specifications. Mold designers utilize sophisticated software to create detailed blueprints that factor in everything from product size to intricate features. This ensures an accurate representation of the final product and sets the stage for a flawless manufacturing journey.

The Importance of ABS Mold Design

ABS mold design is integral to the success of the manufacturing process. A perfect design brings efficiency and quality, reducing problems during production. Mold design involves precise engineering and innovation, ensuring that the blueprint caters to every potential scenario during molding. By incorporating advanced techniques, manufacturers ensure product durability and aesthetics.

One key aspect of ABS mold design is its role in preparing for the injection molding stage—raw materials transform into components with pinpoint accuracy. This process, executed with cutting-edge injection molding machinery, ensures minimal waste and consistent results. By prioritizing design in ABS mold manufacturing, businesses achieve better outcomes without unnecessary expenditure or time delays.

ABS Mold Components and Assembly

ABS mold manufacturing culminates in the creation of ABS mold components and their subsequent assembly. High-grade materials and skilled craftsmanship ensure that mold components withstand rigorous industrial use while delivering superior performance. This stage seamlessly integrates all parts to produce flawless products that meet clients’ exact needs.

Mold Assembly is the final stage, where each ABS mold component is expertly fitted into its respective place, guaranteeing a flawless final product. This meticulous phase ensures that all parts fit together seamlessly, enhancing product reliability, aesthetic appeal, and functional utility. This attention to detail reinforces the reputation of ABS mold manufacturing as a benchmark in quality.

Why Choose One-Stop Solutions for Molding?

For those seeking unmatched precision and efficiency, the One-Stop Solutions for Molding is a game-changer. This comprehensive process simplifies the complex manufacturing cycle into four critical stages: Mold Design, Mould Making, Injection Molding, and Mold Assembly. From conceptualizing your product with cutting-edge design software to transforming raw materials into high-quality components using state-of-the-art machinery, every step is engineered for excellence.

Whether you're producing intricate parts for electronics or large-scale industrial components, this integrated solution ensures flawless results at every stage. By choosing One-Stop Solutions for Molding, you’re embracing an innovative manufacturing approach tailored for success. Trust in ABS mold manufacturing and its advanced processes to deliver excellence and transform your ideas into reality.