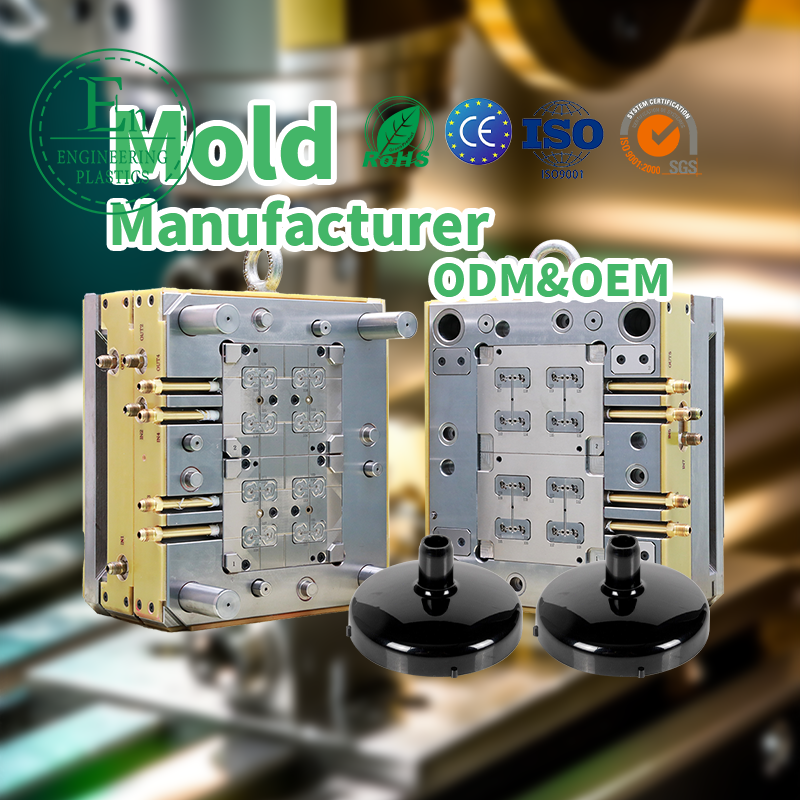

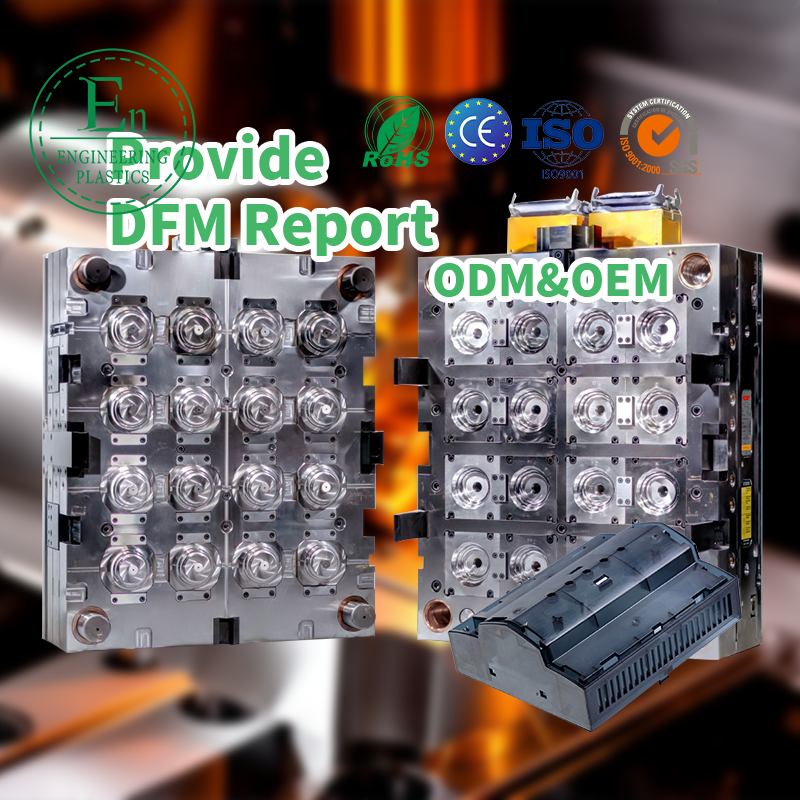

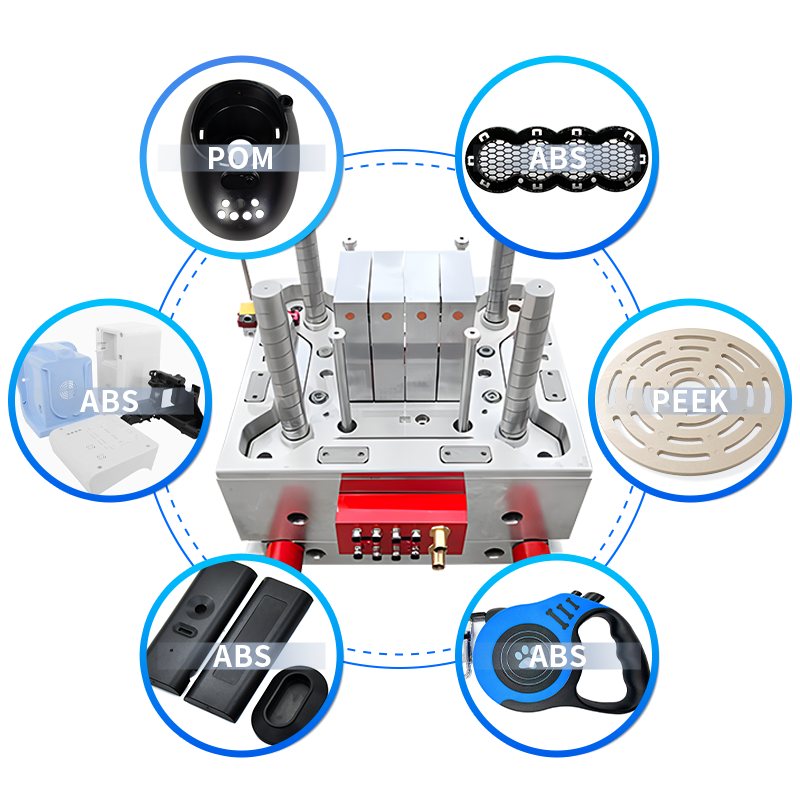

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

The Dawn of a New Era in Manufacturing: Injection Mold Metal

The world of modern manufacturing incessantly strives for greater precision, enhanced durability, and more complex component geometries. In this relentless pursuit of excellence, **injection mold metal** technology has emerged as a transformative force, offering a superior pathway to produce intricate, high-volume metal parts. This innovative process is not just an alternative; it represents a significant leap forward, reshaping how industries from aerospace and automotive to medical and consumer electronics approach the creation of critical metal components with unmatched accuracy and efficiency. If you're seeking a method that combines strength with intricate design possibilities, your search unequivocally ends here.

Unlocking Superior Performance: The Unmatched Advantages of Injection Mold Metal

Why should you strongly consider **injection mold metal** for your manufacturing needs? The advantages are compelling and numerous. Firstly, the inherent strength and robustness of metal parts produced through this method ensure exceptional longevity and resistance to demanding operational conditions, including high wear, extreme temperatures, and corrosive environments. Secondly, this technology liberates designers, allowing for the creation of complex, three-dimensional geometries and intricate features that are often too costly or outright impossible to achieve through traditional machining or casting methods. Furthermore, a wide array of metal alloys can be utilized, offering tailored solutions for specific performance requirements. For mass production, the near-net-shape capability significantly reduces material waste and minimizes the need for extensive secondary machining operations, translating into tangible cost savings without compromising on quality. This is not just manufacturing; it's smart engineering.

The Backbone of Precision: Advanced Injection Mold Equipment

To truly harness the full potential of metal injection molding and achieve consistently superior results, reliance on advanced **injection mold equipment** is absolutely indispensable. This specialized machinery encompasses a range of sophisticated components, from high-pressure injection molding machines meticulously designed to handle the unique properties of molten metal feedstock, to intricately crafted tooling and dies typically made from hardened, wear-resistant tool steels. Furthermore, controlled atmosphere sintering furnaces are critical for the debinding and final consolidation stages, transforming the 'green' part into a dense, functional metal component. The precision, control, and automation capabilities offered by modern **injection mold equipment** are not just desirable but fundamental for maintaining tight dimensional tolerances, ensuring microstructural integrity, and achieving the consistent part quality demanded by today's competitive industries. Investing in, and properly maintaining, state-of-the-art **injection mold equipment** is a clear indicator of a commitment to manufacturing excellence and innovation; it's the bedrock upon which reproducible quality is built.

Shaping Futures: Diverse Opportunities in Injection Mold Jobs

The rapid expansion and increasing sophistication of the metal injection molding sector have cultivated a strong and growing demand for skilled professionals, leading to a wealth of diverse and rewarding **injection mold jobs**. The opportunities span the entire production lifecycle, from innovative design engineers and material scientists who conceptualize the parts and optimize metal powder formulations, to highly skilled CNC machinists and toolmakers who create the precision molds. On the shop floor, experienced technicians are needed to operate and maintain the complex **injection mold equipment**, while meticulous quality assurance specialists and metrologists play a crucial role in ensuring every component meets stringent industry standards and client specifications. Pursuing a career through **injection mold jobs** means engaging with a cutting-edge technological field that is perpetually evolving. It offers continuous learning challenges and the profound satisfaction of contributing to the creation of critical components that power innovation across numerous vital industries. This isn't just a job; it's a chance to be at the forefront of manufacturing's future.

The Strategic Imperative: Why Your Business Must Embrace Injection Mold Metal

In today's fiercely competitive global marketplace, the decision to adopt **injection mold metal** processes is more than a technical choice; it's a strategic imperative. This technology empowers your business to innovate beyond previous limitations, producing parts with superior mechanical properties, intricate designs, and excellent surface finishes. Consider the competitive edge gained by offering products that are stronger, last longer, and can incorporate more complex functionalities. Unlike conventional metal forming techniques that often lead to significant material waste and require multiple costly machining steps, metal injection molding offers a streamlined, near-net-shape solution that drives down per-part costs in high-volume scenarios. Investing in this technology is an investment in your company's ability to deliver superior value, respond agilely to market demands, and solidify its position as an industry leader. The question isn't whether you can afford to adopt it, but whether you can afford not to.

Forging Ahead: The Enduring Power of Metal Injection Molding

The trajectory of advanced manufacturing is undeniably intertwined with breakthroughs in material science and production methodologies, and **injection mold metal** technology stands proudly at the vanguard of this evolution. As the appetite for smaller, more intricate, and higher-performing metal components continues to surge across diverse sectors, the mastery of this process, supported by sophisticated **injection mold equipment** and fueled by skilled professionals in rewarding **injection mold jobs**, becomes increasingly crucial. Opting to integrate metal injection molding into your operations is not merely adopting a new manufacturing process; it's a strategic embrace of enhanced product quality, unparalleled design freedom, and a significantly stronger competitive posture. The transformative impact on your production capabilities and product innovation is profound and far-reaching – the benefits are simply too compelling to overlook. Embrace the future of metal component manufacturing today.