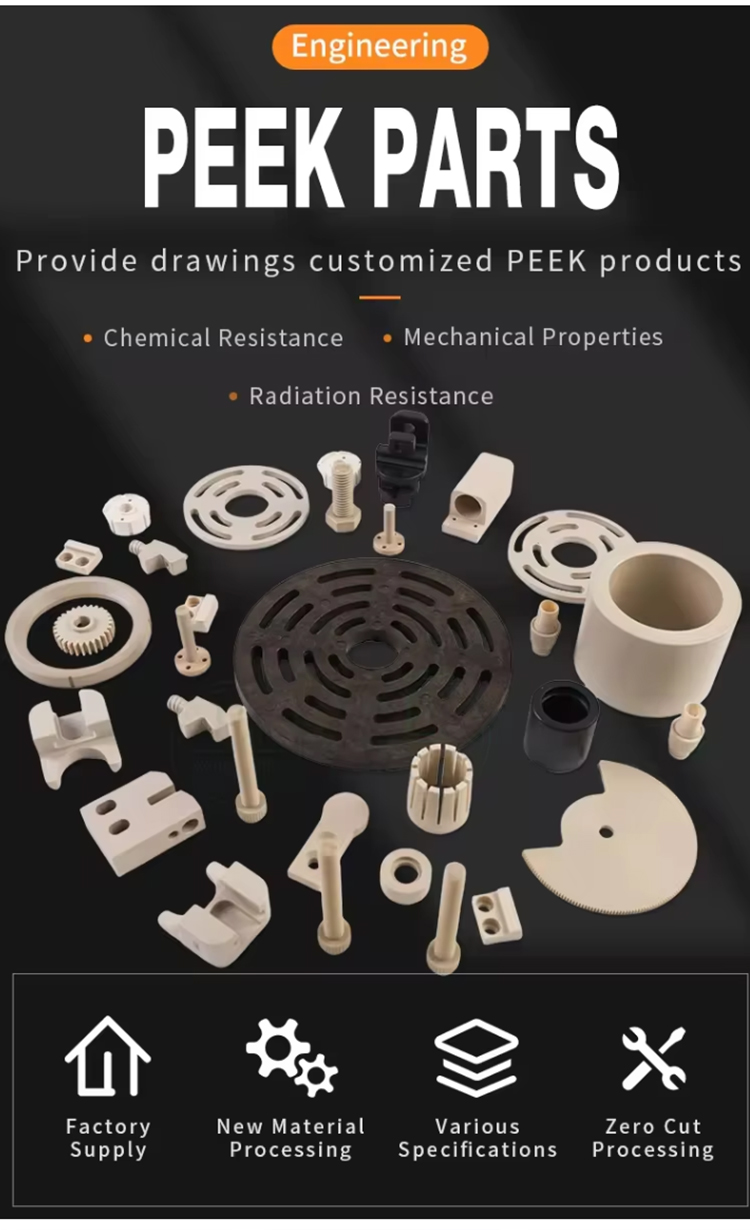

PEEK parts have become a cornerstone of modern industries, known for their outstanding performance and material versatility. PEEK, or polyether ether ketone, is a high-performance thermoplastic that delivers superior mechanical and thermal properties, making it ideal for use in various industrial components. Whether you're looking for industrial gears, rollers, or custom screws, PEEK parts offer unmatched reliability and durability that set them apart in high-demand applications.

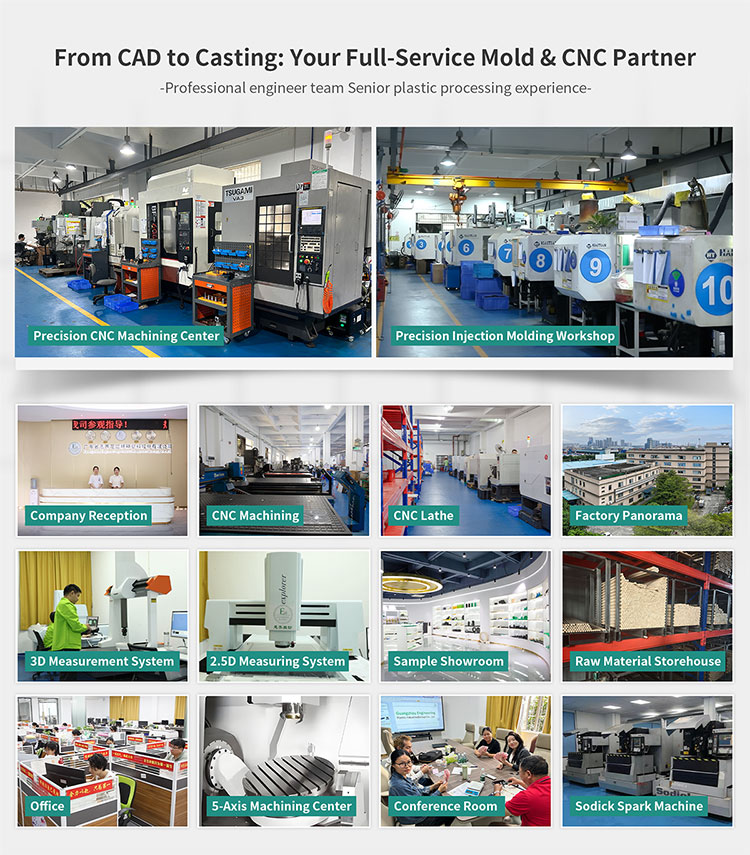

Finding a reliable PEEK parts supplier or manufacturer is critical for industries like automotive, aerospace, and robotics, where precision and material strength are non-negotiable. Leading players in the CNC machining industry have stepped up to incorporate PEEK and similar high-performance materials into their engineering processes. The result? A lineup of intricately designed CNC machining parts tailored to meet specific industrial needs. These precision-engineered components include a variety of parts like guide rails, sprockets, and industrial wheels. Crafted for applications requiring advanced wear resistance, chemical stability, and thermal endurance, PEEK components have become a go-to solution for engineers and manufacturers worldwide.

One notable feature of these PEEK parts is their material versatility. Often combined with other high-performance materials like stainless steel and durable alloys, PEEK components are engineered to deliver exceptional wear resistance and longevity. These properties ensure that the parts can withstand the demands of rigorous operational environments, reducing maintenance needs and extending the lifespan of equipment. For example, precision screw conveyors made with PEEK are ideal for industries like food processing and pharmaceuticals where durability and hygiene go hand in hand. Likewise, custom gears, engineered for low friction and high efficiency, provide an excellent solution for mechanical systems in need of robust and lightweight components.

Customization is yet another hallmark of modern PEEK parts manufacturing. Unlike off-the-shelf products, these components can be tailored to meet the exact requirements of a project. Whether designing smooth-rotational industrial wheels and casters for mobility or crafting lightweight rail systems for enhanced motion precision, CNC machining companies excel in creating bespoke PEEK components to optimize performance. Advanced design features such as vibrant color coding in green, yellow, or blue help engineers quickly identify key parts, making assembly, maintenance, and troubleshooting significantly easier. This attention to detail underscores PEEK’s increasing role as a fundamental material in innovative industrial design.

Additionally, the precision engineering behind these parts highlights their adaptability across various sectors. The meticulous machining process ensures each part meets exact specifications, offering optimal compatibility and function in custom assemblies. For instance, guide rails and sprockets crafted with PEEK have proven invaluable in robotics and automation, providing high precision and reliability in complex, high-performance settings. This level of workmanship not only enhances mechanical efficiency but also lends a sleek, aesthetically modern touch to machinery—a blend of functionality and artistry in industrial design.

From custom gears to multi-functional sprockets, the latest in CNC machining innovation showcases how PEEK and similarly durable materials are revolutionizing industrial parts. Companies looking to enhance their machinery’s efficiency, durability, and precision should explore the extensive range of PEEK components manufactured today. With their ability to endure harsh operational conditions while maintaining pristine functionality, these components represent a forward-thinking solution for industries aiming to achieve maximum productivity. For anyone considering an upgrade or replacement of critical machinery parts, PEEK parts from reputable suppliers and manufacturers are the key to elevating project excellence.

Investing in high-quality PEEK components is not just an option but a necessity for businesses aiming to thrive in a competitive, high-performance industrial landscape. With PEEK parts, professionals are equipped to achieve operational excellence while ensuring longevity and reliability in every application.