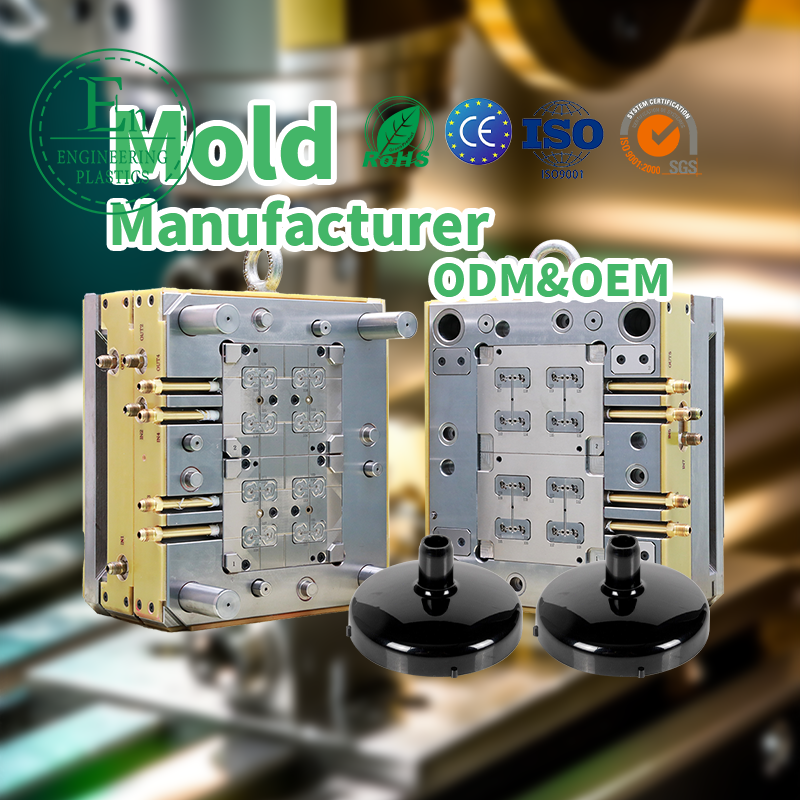

We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

The Foundation of Modern Manufacturing

In the world of modern manufacturing, few processes are as fundamental and versatile as plastic injection molding. This technology is the unsung hero behind countless products we use daily, from complex automotive components to simple household items. It offers an unparalleled combination of speed, precision, and cost-effectiveness, making it the go-to method for high-volume production. Understanding the principles of this process reveals why it has become a cornerstone of global industry, enabling the creation of intricate and durable plastic parts on a massive scale.

What is Plastic Injection Molding?

At its core, plastic injection molding is a manufacturing process for producing parts by injecting molten material into a mold. The process begins with thermoplastic or thermosetting polymer resins, which are fed into a heated barrel in the form of small pellets. These pellets are melted, mixed, and then forced into a mold cavity under high pressure. Once inside the mold, the material cools and solidifies, taking on the exact shape of the cavity. This injection type method is renowned for its ability to produce parts with complex geometries and fine details with exceptional consistency. The precision of the mold directly translates to the precision of the final product, allowing for tight tolerances that are repeatable across millions of cycles.

The Step-by-Step Process

The injection molding cycle is a carefully orchestrated sequence of events that can be broken down into four main stages. First is the clamping stage, where the two halves of the mold are securely closed by a powerful clamping unit. Next is the injection stage, where the molten plastic is rapidly injected into the closed mold. The pressure is maintained to ensure the cavity is completely filled. The third stage is cooling. The molten plastic inside the mold begins to cool as it makes contact with the interior surfaces, solidifying into the desired shape. This step is critical as it determines the final properties and dimensional stability of the part. Finally, the ejection stage occurs. After the part has sufficiently cooled, the mold opens, and an ejection mechanism, typically using pins or plates, pushes the finished part out of the cavity. The cycle then repeats, ready to create the next part.

Key Advantages and Applications

The widespread adoption of the injection type molding process is due to its significant advantages. Its high efficiency makes it ideal for mass production, as cycle times can be as short as a few seconds, leading to a low cost per part. The process allows for immense design flexibility, enabling the creation of complex shapes that would be difficult or impossible to produce with other methods. Furthermore, there is a vast selection of materials and colors available, allowing products to be tailored for specific performance requirements and aesthetic preferences. This versatility has made plastic injection molding indispensable across numerous industries, including automotive for creating dashboards and bumpers, medical for manufacturing syringes and device housings, electronics for producing casings, and consumer goods for everything from toys to kitchenware.