We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

Our expertise includes:

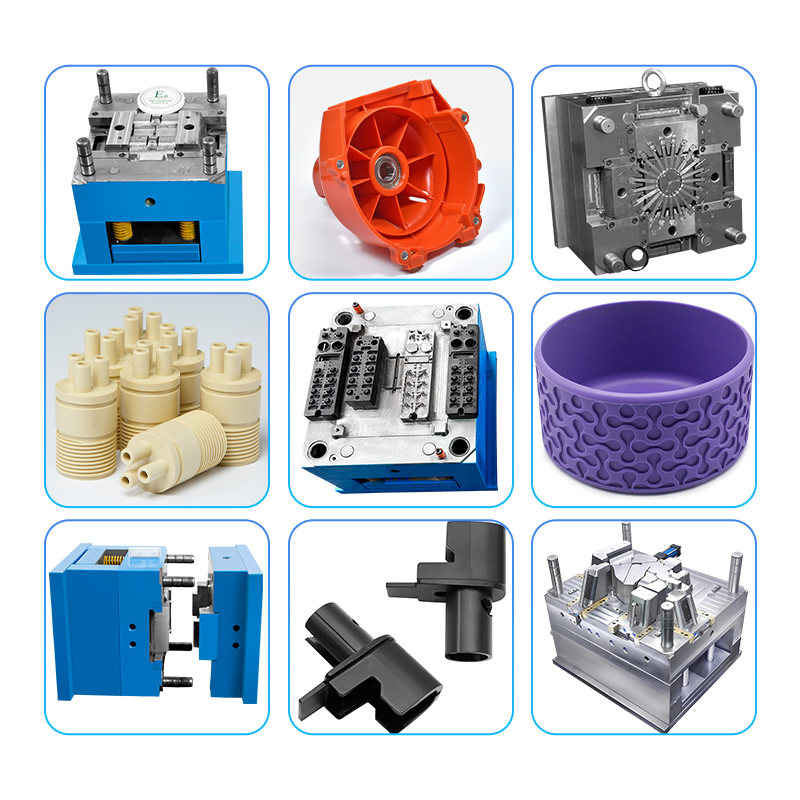

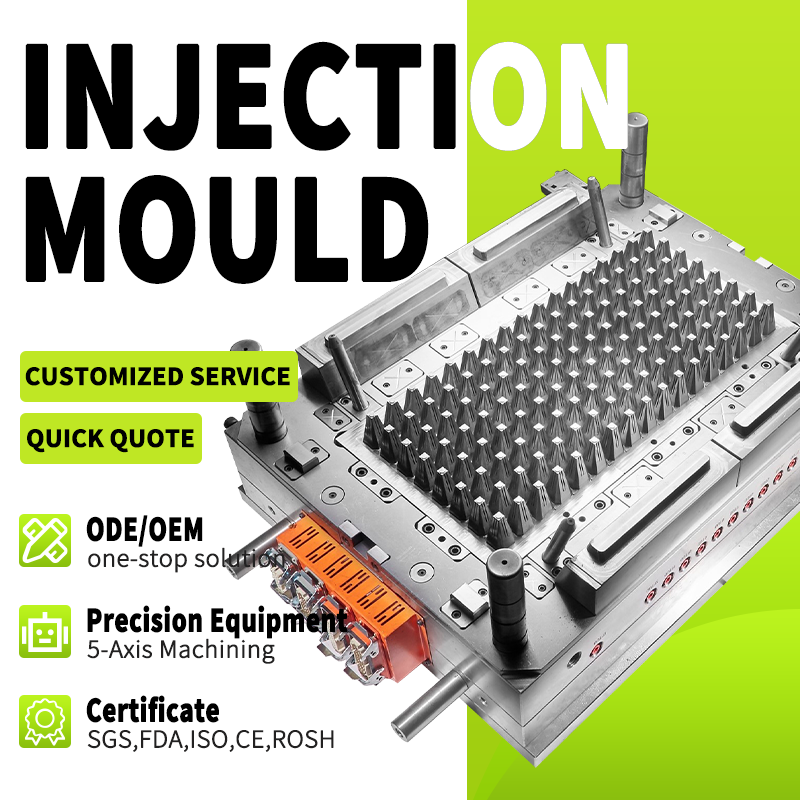

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

moulds for plastic injection

Introduction to Mouldings Plastic Model

Mouldings plastic models have revolutionized the way industries manufacture diverse products. At the heart of this innovation are moulds for plastic, which form the backbone of the plastic modeling process. These plastic models are crucial in creating precise and accurate components used across various applications, including automotive, aerospace, and consumer goods.

The Importance of Moulds for Plastic

Moulds for plastic are indispensable tools in the manufacturing industry. They serve as the master pattern for producing numerous identical copies of a product with consistent quality and dimensions. These moulds enable manufacturers to achieve intricate designs and detail that would be challenging with other materials. The versatility offered by plastic moulds makes them highly sought after, allowing for creativity in product design and engineering. From simple household items to complex machinery parts, moulds for plastic play a pivotal role in ensuring high standard production.

Understanding Moulds for Plastic Injection

A specialized category within moulds for plastic is moulds for plastic injection. Plastic injection moulding is a manufacturing process whereby molten plastic is injected into a mould cavity, cooled or cured, and then ejected, resulting in a finished part. This technique is renowned for its efficiency in producing large quantities of identical products. It's particularly beneficial in industries that require quick turnaround times without compromising on quality. The moulds for plastic injection are designed to withstand high pressure executed during the injection process, ensuring durability and longevity.

Applications and Benefits

The applications of mouldings plastic model are vast. In the automotive industry, plastic models are used for producing dashboards, light fixtures, and other components. In electronics, they are essential in manufacturing casings and internal parts. The benefits of using mouldings plastic models are numerous. They are cost-effective, allow for rapid production cycles, and enable companies to maintain high precision and quality standards. Moreover, the lightweight nature of plastics reduces shipping costs and improves fuel efficiency in the automotive sector, underscoring the environmental advantage.

In conclusion, mouldings plastic model and the associated technology like moulds for plastic and moulds for plastic injection are integral to modern manufacturing. Their influence stretches across industries, enhancing product design, efficiency, and quality while supporting sustainable practices. As technologies evolve, the capabilities of plastic moulding continue to expand, offering an exciting frontier for innovation and development.