We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

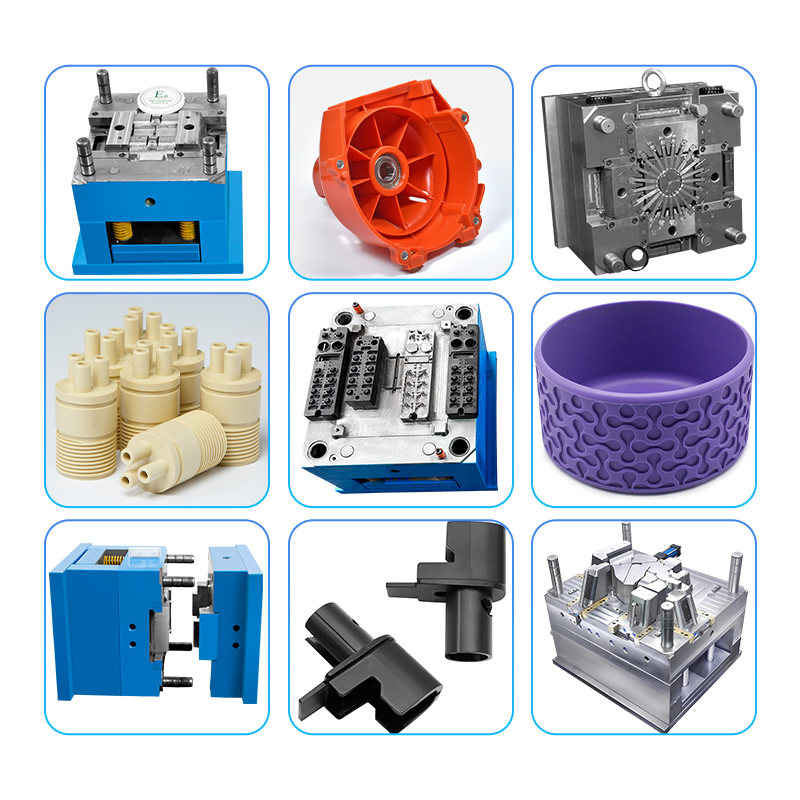

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of advanced manufacturing, the drive for creating stronger, lighter, and more complex components is relentless. One of the most innovative techniques that meets this demand is precision insert molding. This process combines different materials, typically metal and plastic, into a single, integrated part during the molding cycle. It eliminates the need for post-molding assembly, reducing costs and creating a more robust final product. By seamlessly integrating inserts into a plastic part, manufacturers can achieve designs and functionalities that would be impossible with traditional molding methods alone.

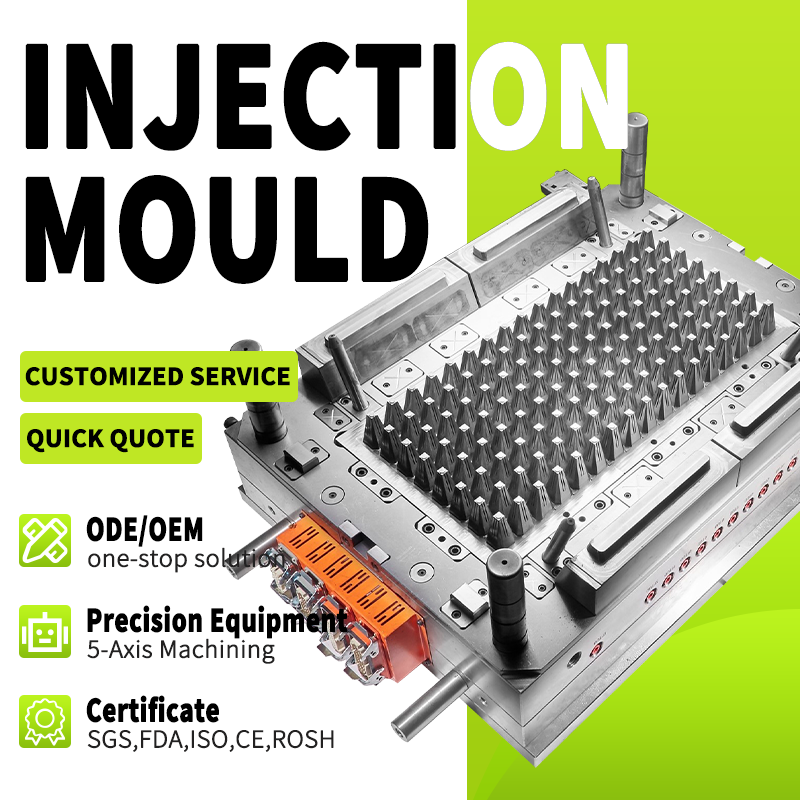

What is Precision Insert Molding?

At its core, precision insert molding is a sophisticated process where a pre-fabricated component, known as the insert, is placed into a custom-designed mold cavity. This insert can be made from various materials, but is most commonly metal, such as brass, steel, or aluminum. Once the insert is securely positioned, molten thermoplastic or thermoset material is injected into the mold, flowing around and encapsulating the insert. The plastic then cools and solidifies, forming a strong mechanical and often chemical bond with the insert. The key to this process is the 'precision' aspect, which involves extremely tight tolerances in both the insert's placement and the final part's dimensions. A high-quality plastic injection mold is essential to hold the insert steady against the immense pressure of the injected material, ensuring perfect alignment and integration.

The Key Benefits of Custom Molding with Inserts

The advantages of using this technique are numerous, making it a preferred choice for many high-stakes industries. One of the primary benefits is the significant enhancement in part strength and durability. The metal insert provides structural reinforcement, threaded fastening points, or electrical conductivity, while the plastic overmold provides a lightweight, corrosion-resistant, and aesthetically pleasing exterior. This method of custom molding also drastically reduces assembly costs and time. Instead of manufacturing a plastic part and a metal part separately and then joining them with screws, adhesives, or clips, insert molding accomplishes this in one efficient step. This consolidation of processes not only saves money but also improves the overall reliability of the component, as the bond created during molding is far superior to most secondary assembly methods.

The Technology Behind a Perfect Plastic Injection Mold

Achieving success with precision insert molding requires a deep understanding of materials science and process engineering. The design of the plastic injection mold is paramount. It must not only create the external shape of the part but also feature intricate mechanisms to hold the insert securely in position during the injection phase. Engineers must account for material shrinkage rates and the different thermal expansion coefficients of the plastic and the insert to prevent stress cracks or part failure. Material selection is another critical factor; the chosen plastic must be compatible with the insert material to ensure a strong bond and long-term performance. Furthermore, the process itself is highly controlled, with advanced machinery monitoring injection speed, pressure, and temperature to guarantee consistent quality and prevent damage to the delicate inserts. Automation, such as robotic arms for insert placement, is often employed to increase speed, accuracy, and repeatability in high-volume production.

Applications Across Industries

The versatility of this technology has led to its adoption across a wide range of industries. In the automotive sector, it's used to create sensors, electrical connectors, and knobs with embedded metal threads. For consumer electronics, this process is ideal for manufacturing durable housings with integrated charging ports, antenna components, and threaded standoffs for circuit boards. The medical field relies on this technology for creating robust surgical instruments, where a stainless steel tool is overmolded with a biocompatible plastic handle for improved ergonomics and sterilization. This method of custom molding also finds use in aerospace for producing lightweight components that still require the strength of metal in critical areas. In each case, the process delivers a reliable, high-performance part that is optimized for its specific function.

Partnering for Success in Custom Molding

In summary, precision insert molding stands out as a powerful manufacturing solution for creating complex, multi-material components with superior performance and reduced assembly costs. By combining the strength of metal with the versatility of plastic in a single, streamlined process, it opens up new possibilities for product design and innovation. However, the complexity of designing a functional plastic injection mold and perfecting the molding parameters requires significant expertise. For any company looking to leverage this advanced technique, partnering with a specialist in custom molding is crucial to transforming a complex design concept into a successful, high-quality finished product.