We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

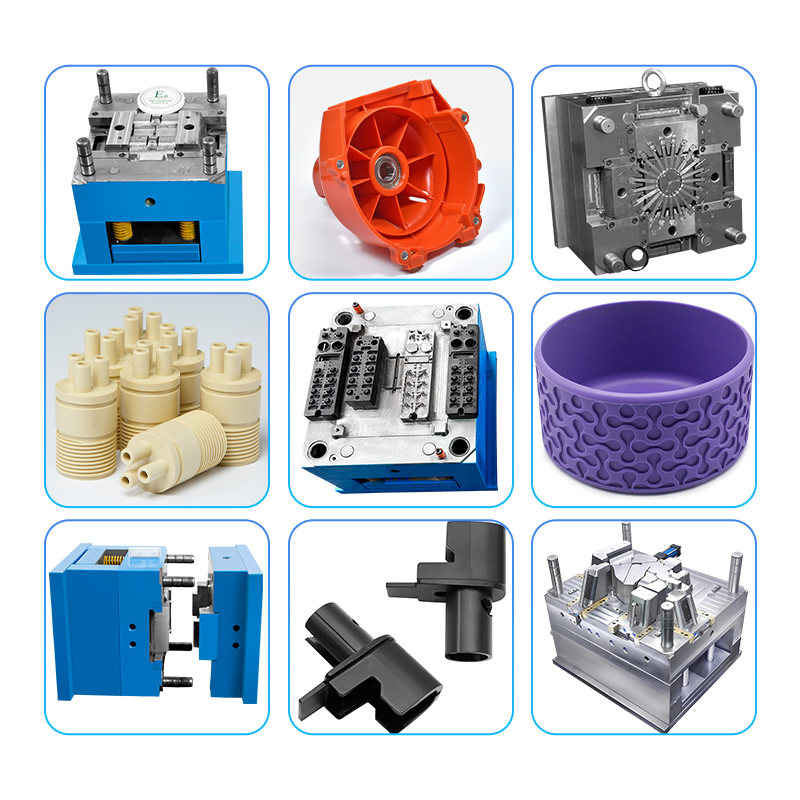

Our expertise includes:

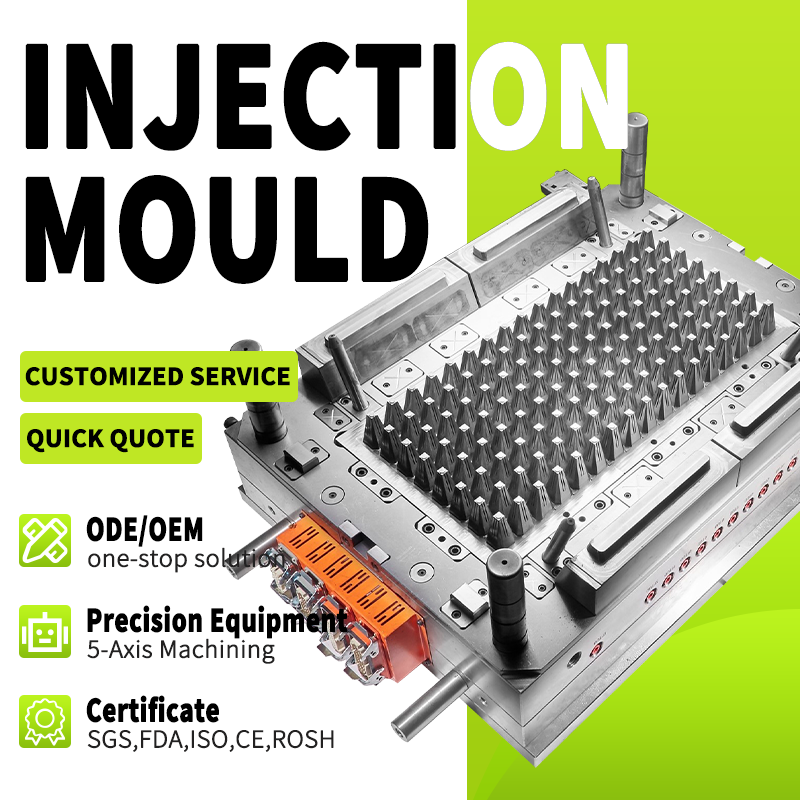

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

Understanding OEM Plastic and Its Significance

OEM plastic, short for Original Equipment Manufacturer plastic, plays a critical role in the manufacturing and production industries. This term refers to plastic components that are custom-made, typically through processes such as injection molding, for specific products or applications. The production of OEM plastic parts is significant because it allows for the creation of high-quality, custom components that meet the exact specifications of the equipment or devices in which they will be used. Using OEM plastic ensures that the final products are not only functional but also reliable and durable.

The Role of OEM Plastic Injection Molds in ABS Production

One of the commonly used materials in OEM plastic production is ABS, known for its strength and versatility. OEM plastic injection molds for ABS are essential in crafting precise and intricate parts essential for various industrial applications. Through injection molding, manufacturers can produce complex shapes and designs, efficiently responding to specific needs and requirements. The molding process involves injecting plastic into pre-designed molds, which then solidifies into the desired shape. This method is not just cost-effective but also improves production speed while maintaining consistency in quality.

The Benefits of Custom OEM Plastic Parts

Choosing OEM plastic parts offers numerous benefits, especially for businesses aiming to enhance the quality and functionality of their products. Custom OEM plastic parts allow manufacturers to benefit from parts that are tailored specifically to their product's requirements, ensuring that fit, form, and function are precisely aligned. This can lead to increased product performance and customer satisfaction. Additionally, OEM plastic parts can contribute to reducing waste and lowering production costs, as they are designed to minimize excess material use and improve the manufacturing process's efficiency.

In summary, the importance of OEM plastic, including its application through OEM plastic injection molds for materials like ABS, cannot be understated. Whether it's producing intricate components for intricate machinery or more straightforward OEM plastic parts for consumer products, these custom solutions are integral to modern manufacturing, enabling innovation, enhancing product quality, and fostering development in various industries.