We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

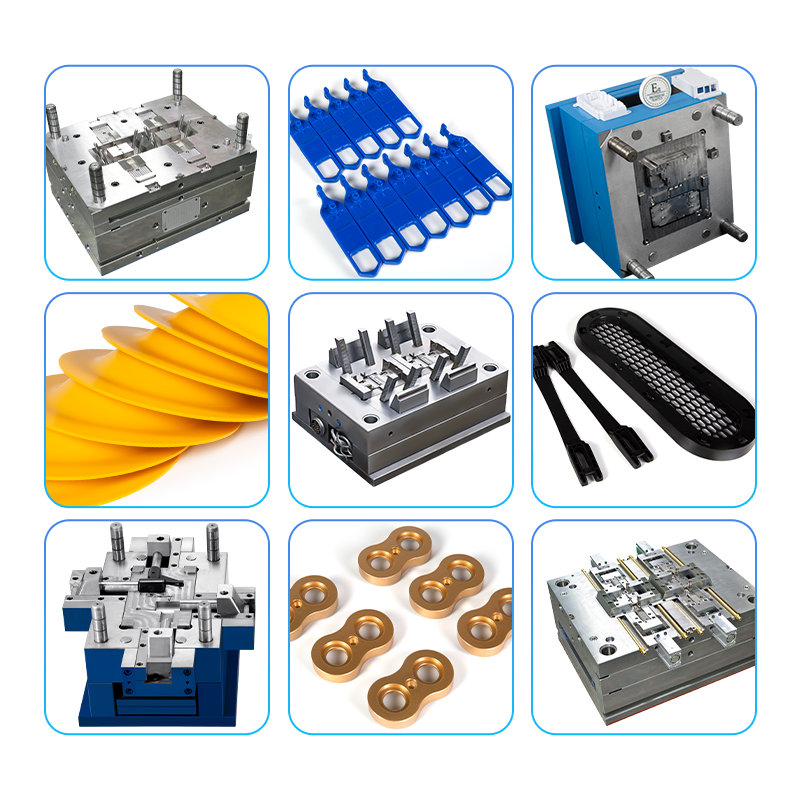

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

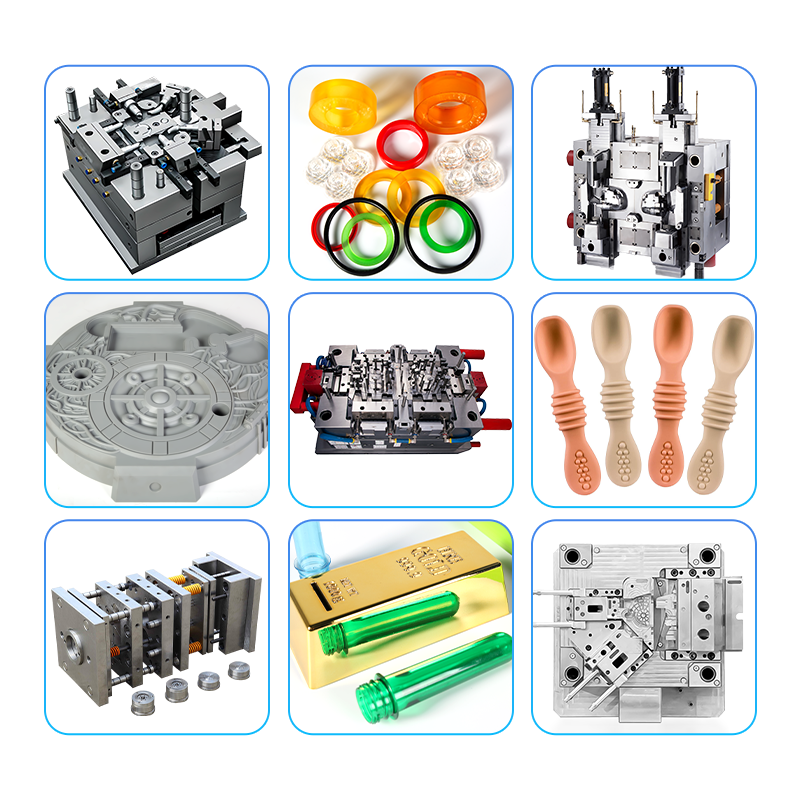

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

The Core of Modern Production: High-Quality Molds

In the world of mass production, consistency, precision, and efficiency are paramount. At the heart of achieving these goals lies a critical component: the mold. High-quality vormen, or molds, serve as the foundational blueprint for countless products we use every day. From simple plastic containers to complex automotive components, the quality of the final product is directly tied to the quality of the mold used to create it. A well-engineered mold not only ensures that every part is identical but also enhances the speed and cost-effectiveness of the entire manufacturing process. Investing in superior mold design and fabrication is not an expense but a strategic decision that pays dividends through reduced waste, lower cycle times, and enhanced product integrity.

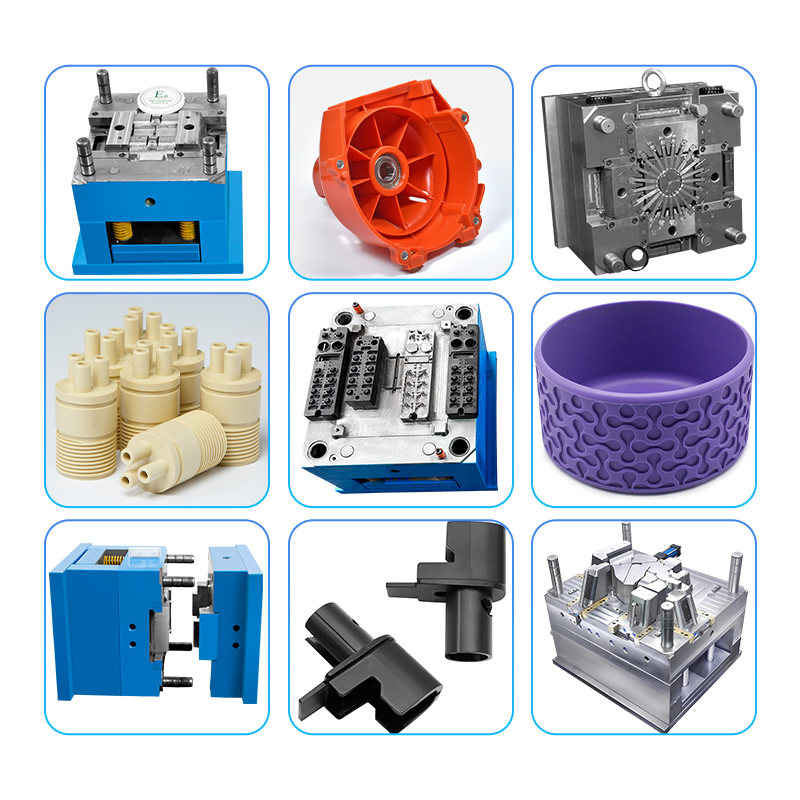

Understanding the Injection Molding Process

One of the most common manufacturing techniques that relies on these precision molds is injection molding, or spuitgieten. This process involves injecting molten material, typically a thermoplastic or thermosetting polymer, into a mold cavity under high pressure. Once the material fills the cavity, it cools and solidifies, taking the shape of the mold. The mold then opens, and the finished part is ejected. The success of spuitgieten is entirely dependent on the mold's design, which must account for factors like material flow, cooling channels, and air venting to prevent defects and ensure a perfect finish. The synergy between a robust mold and a finely-tuned injection molding process is what enables the creation of intricate and durable parts at a massive scale.

The Repetitive Cycle of Precision

The efficiency of modern manufacturing hinges on the ability to repeat a production cycle flawlessly thousands or even millions of times. The continuous cycle of creating forms, or in this repetitive context, vormen, is the engine of high-volume production. This repetitive nature makes the durability and precision of the tool paramount. For the spuitgieten process, the mold must withstand immense pressure and temperature fluctuations without warping or degrading. Each cycle—clamping the mold halves together, injecting the plastic, holding the pressure, cooling the part, and ejecting it—must be executed with micron-level accuracy. Any deviation can lead to defects, material waste, and costly downtime, highlighting why the initial investment in a superior mold is crucial for long-term operational success and profitability.

Materials and Applications Across Industries

The versatility of using vormen in manufacturing is further enhanced by the vast array of materials that can be used. While plastics are the most common, the process can also be adapted for other materials. This flexibility allows injection molding to serve a diverse range of industries. In the automotive sector, it's used for dashboards, bumpers, and interior components. In the medical field, it produces sterile and precise devices like syringes and implants. Consumer electronics rely on it for casings and buttons, while the packaging industry uses it to create bottles, caps, and containers. The specific requirements of each application dictate both the mold design and the material chosen, showcasing a remarkable synergy between engineering and material science.

Conclusion: The Foundation for Success

Ultimately, the journey from a digital design to a physical product is made possible by the meticulous craft of mold making and the efficiency of the spuitgieten process. A high-quality mold is more than just a tool; it is the cornerstone of reliable, repeatable, and cost-effective manufacturing. For any business looking to bring a product to market, understanding the importance of investing in properly designed and fabricated vormen is the first step toward achieving a high-quality outcome and a competitive edge. This foundational element ensures that the final products are not only aesthetically pleasing but also functionally sound and durable, meeting the high standards of today's consumers and industries.