We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

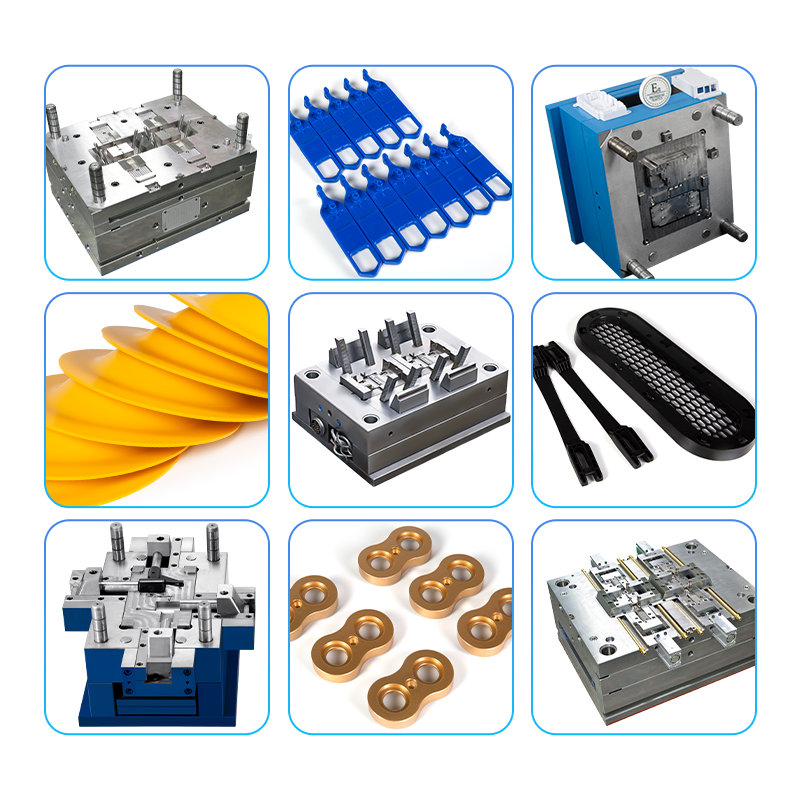

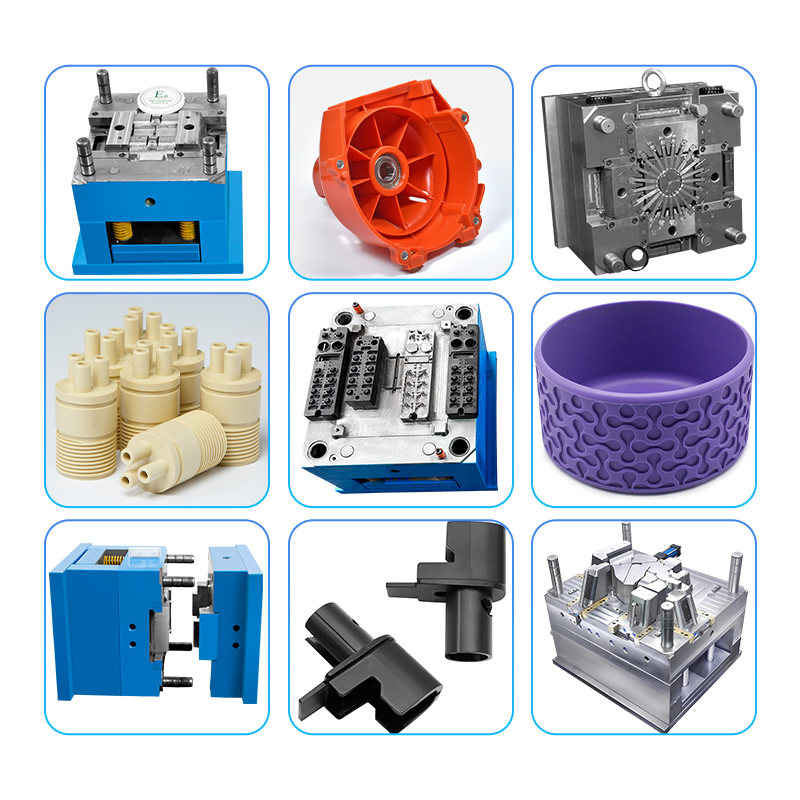

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's highly competitive manufacturing landscape, the quality and precision of plastic components can make or break a product. At the heart of producing these high-quality parts lies a critical tool: the custom plastic injection mold. This sophisticated piece of engineering is the cornerstone of mass production, enabling the creation of identical parts with incredible accuracy and efficiency. Choosing the right process and partner, especially a reputable mold maker, is the first and most crucial step toward turning a product concept into a tangible, successful reality.

Choosing the Right Mold Maker for Your Project

The success of any injection molding project heavily relies on the expertise of the company you partner with. A skilled mold maker does more than just cut steel; they are a crucial collaborator in the product development process. When evaluating a potential partner, consider their experience across different industries, their technological capabilities (such as high-speed CNC machining and EDM), and their portfolio of past projects. A transparent and communicative mold maker will provide detailed Design for Manufacturability (DFM) feedback, helping you optimize your part design to improve quality, reduce cycle times, and lower costs. Their expertise ensures that the mold is not only built to specification but also durable enough to withstand the rigors of high-volume production, ultimately safeguarding your investment.

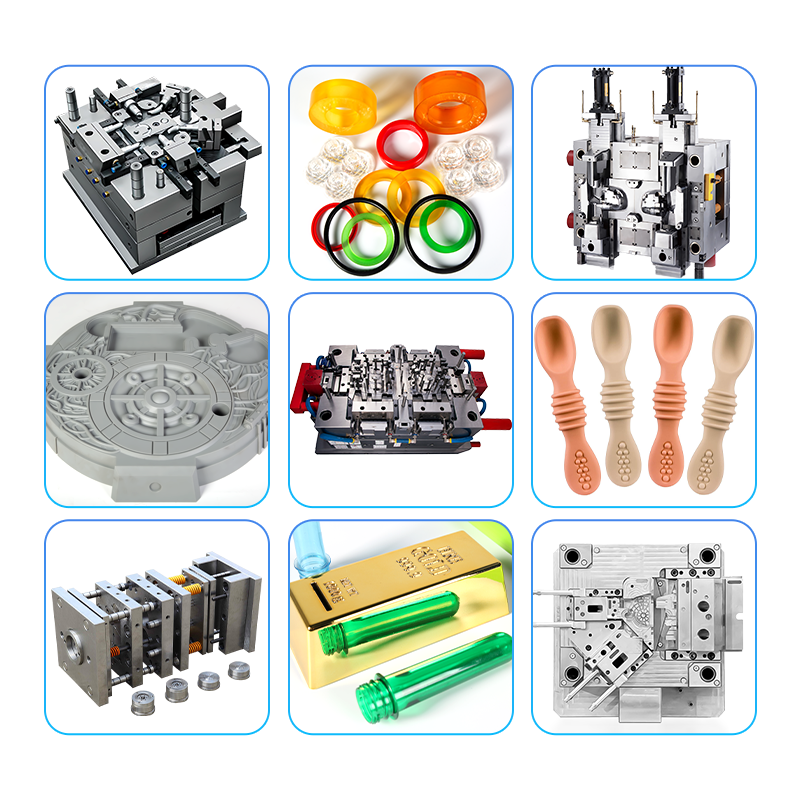

Understanding the Critical Injection Mold Parts

A plastic injection mold is a complex assembly of precisely engineered components working in perfect harmony. Understanding the key injection mold parts helps appreciate the engineering involved and their impact on the final product. The core and cavity are the two halves that form the shape of the part. The sprue, runners, and gates create the pathway for molten plastic to travel from the injection molding machine's nozzle into the cavity. Ejector pins are responsible for pushing the solidified part out of the mold after each cycle. Other critical injection mold parts include the cooling channels, which regulate the mold's temperature to ensure consistent cooling and minimize warping, and the venting system, which allows trapped air to escape the cavity as plastic flows in. The quality and precision of each of these components are paramount for producing defect-free parts.

From Design to Reality: The Custom Mold Process

Creating a custom plastic injection mold is a multi-stage process that demands precision at every step. It begins with a comprehensive design phase, where engineers use advanced CAD software to model the mold based on the final part design. This is followed by a crucial DFM analysis to identify any potential manufacturing issues before any metal is cut. Once the design is finalized, the manufacturing process begins. High-strength steel or aluminum blocks are machined with extreme accuracy using CNC mills, lathes, and electrical discharge machining (EDM) to create the intricate features of the core and cavity. After machining, the surfaces are meticulously polished to achieve the desired finish. Finally, all components are assembled, and the mold undergoes rigorous testing, known as T1 trials, to produce initial samples and verify that the custom plastic injection mold performs exactly as intended.

Why a Quality Custom Plastic Injection Mold is a Smart Investment

While the upfront cost of a high-quality mold can seem significant, it is a wise long-term investment that pays dividends. A well-built custom plastic injection mold guarantees exceptional consistency and repeatability, ensuring that every part produced, from the first to the millionth, meets the exact same specifications. This level of quality control drastically reduces defect rates, saving money on material waste and rework. Furthermore, durable molds made from premium materials require less maintenance and have a much longer production life, leading to lower overall part costs. Ultimately, investing in a superior mold built by an experienced mold maker minimizes production risks, accelerates your time to market, and builds a foundation for a successful and profitable product line. This strategic approach separates industry leaders from the rest, proving that quality tooling is not an expense but a competitive advantage.