We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

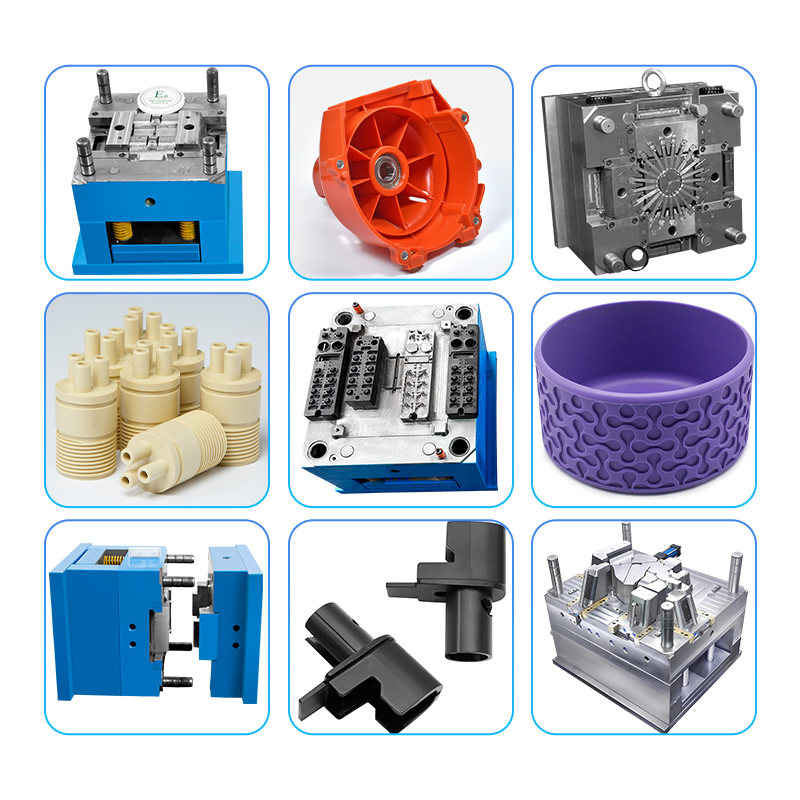

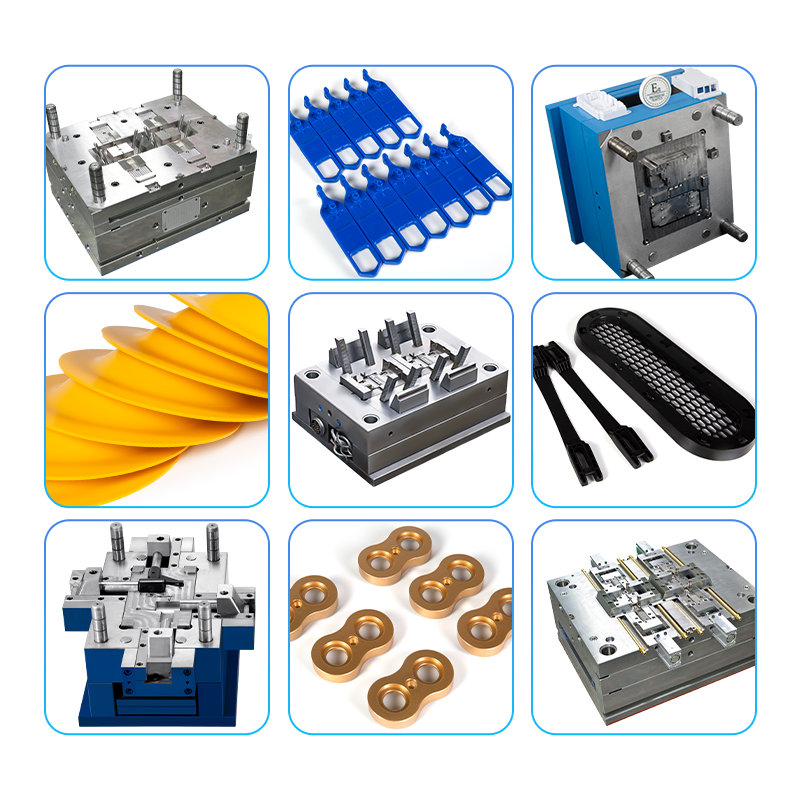

Our expertise includes:

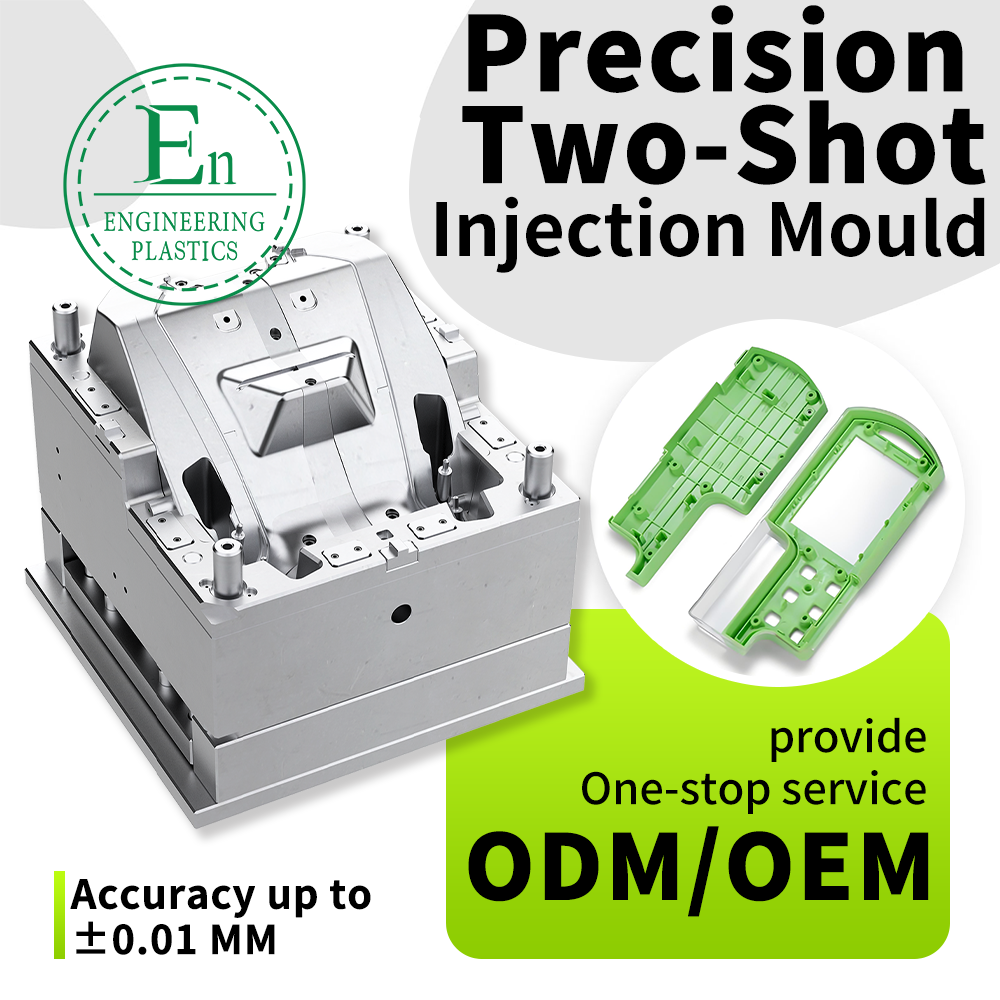

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

The Foundation of Modern Manufacturing

In the world of modern production, the ability to create identical, high-quality parts at scale is paramount. This is where advanced manufacturing techniques come into play, with various forms of molding, or 'moldeos', serving as a cornerstone for countless industries. From the automotive sector to consumer electronics and medical devices, the principles of molding allow for the efficient transformation of raw materials into complex, functional products that shape our daily lives. The precision and repeatability offered by these processes are unmatched, making them essential for mass production.

Understanding the 'Molde de Inyección'

The heart of the entire operation is the mold itself, specifically the 'molde de inyección' or injection mold. This is not a simple container but a highly engineered, two-part tool, typically crafted from hardened steel or aluminum. It consists of a cavity, which forms the external shape of the part, and a core, which forms the internal features. Intricate channels are built into the mold for cooling fluids to pass through, ensuring the molten material solidifies at a controlled rate. The design and construction of a 'molde de inyección' demand incredible precision, as any flaw will be replicated in every single part produced. The quality of this tool directly dictates the quality, consistency, and lifespan of the production run.

The Process of 'Moldeo por Inyección'

The manufacturing method that utilizes this tool is known as 'moldeo por inyección', or injection molding. This process is a marvel of efficiency and can be broken down into a few key stages. First, the two halves of the mold are securely clamped together under immense pressure. Next, melted plastic pellets are injected into the mold's cavity until it is completely filled. The plastic is then held under pressure while it cools and solidifies, perfectly taking the shape of the mold's interior. Finally, the mold opens, and an ejector system pushes the finished part out. This entire cycle can take anywhere from a few seconds to a couple of minutes, allowing for the rapid production of thousands or even millions of identical parts.

Why Choose Injection Molding?

The widespread adoption of injection molding stems from its numerous advantages. The primary benefit is its incredible efficiency and low cost per part when manufacturing in high volumes. Once the initial investment in the 'molde de inyección' is made, the automated process allows for rapid production with minimal labor. This method also offers exceptional repeatability, ensuring that the last part is identical to the first. Furthermore, 'moldeo por inyección' supports a vast range of thermoplastic and thermosetting polymers, providing immense flexibility in material properties, colors, and finishes. This versatility makes it one of the most popular forms of 'moldeos' available today.

Applications Across Industries

The impact of injection molding is visible all around us. In the automotive industry, it is used to create everything from dashboards and bumpers to small interior clips and buttons. The medical field relies on it for producing sterile, high-precision components like syringes, surgical instruments, and implantable devices. Consumer electronics, such as smartphone casings, remote controls, and keyboard parts, are almost exclusively made using this technique. Even simple everyday items like bottle caps, plastic containers, and children's toys are products of this fundamental manufacturing process, showcasing its incredible reach and importance.

The Future of 'Moldeos'

As technology continues to advance, so does the field of molding. The future of 'moldeos' points towards even greater precision, automation, and sustainability. Innovations like 3D-printed molds for prototyping, sensor-integrated 'smart molds' that provide real-time data, and the increasing use of recycled and biodegradable plastics are pushing the boundaries of what is possible. These advancements ensure that injection molding will remain a critical and evolving component of the global manufacturing landscape for decades to come, continuing to build the world around us one part at a time.