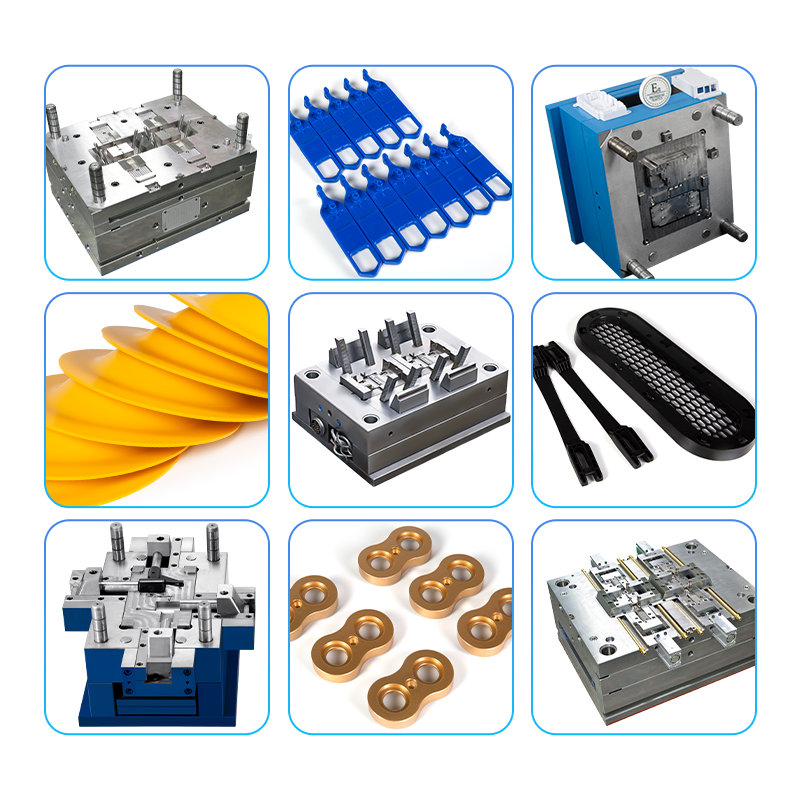

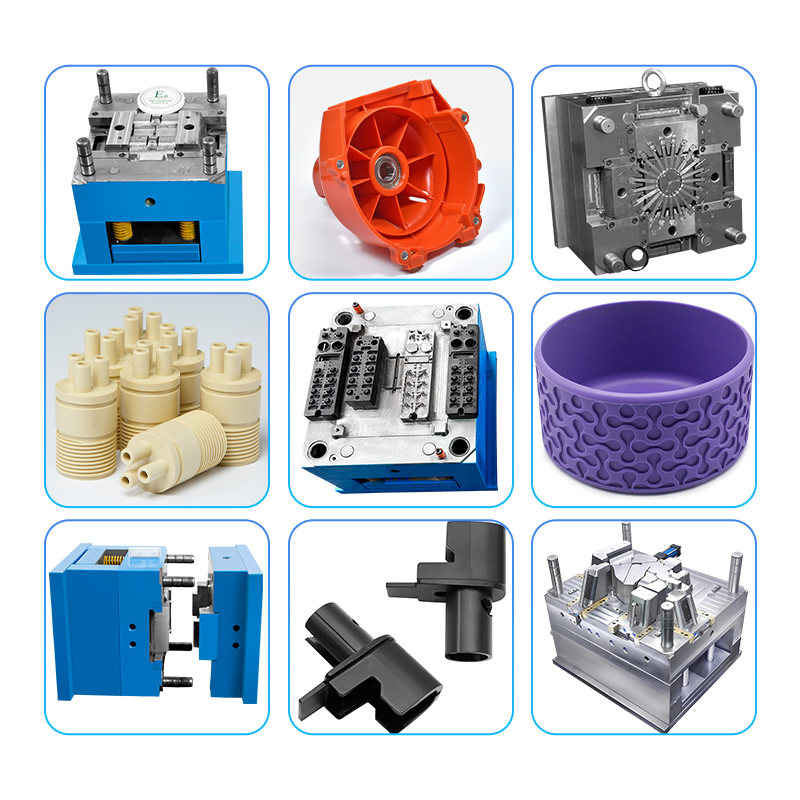

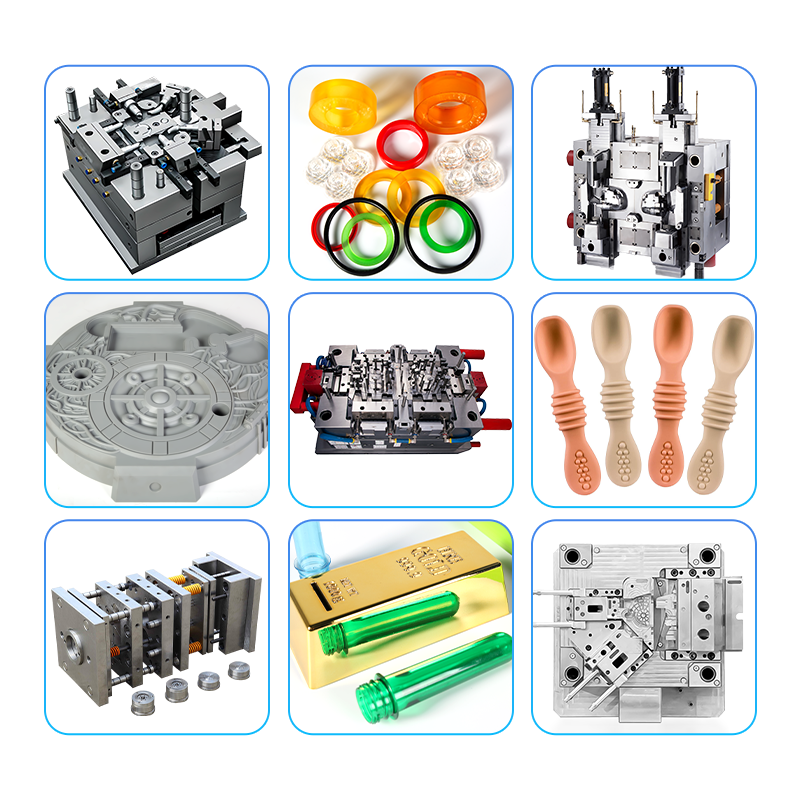

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In today's highly competitive industrial landscape, the demand for components with exceptional quality and accuracy has never been greater. This is where Professional Manufacturing stands out as a critical discipline, moving beyond traditional methods to embrace technology, innovation, and unwavering standards. For businesses in sectors ranging from aerospace to medical devices, partnering with a provider that specializes in advanced manufacturing isn't just an advantage; it's a necessity for creating reliable, high-performance products that meet the rigorous demands of the modern market.

Understanding Precision Manufacturing Services

At the heart of modern production are Precision Manufacturing Services, which involve a set of processes designed to create parts and components with extremely tight tolerances. This level of accuracy, often measured in micrometers, is essential for applications where even the slightest deviation can lead to system failure. These services rely on sophisticated machinery, advanced metrology tools, and a deep understanding of material properties to ensure every piece is identical and conforms perfectly to the design specifications. Whether working with robust metals like titanium and stainless steel or specialized polymers, precision manufacturing guarantees that components function flawlessly within larger, more complex assemblies. This commitment to detail is what enables advancements in critical fields, ensuring the reliability of everything from surgical instruments to satellite components.

The Power of Precision CNC Machining Services

Driving the evolution of precision manufacturing is the widespread adoption of Precision CNC Machining Services. CNC, which stands for Computer Numerical Control, automates machine tools through pre-programmed computer commands. This technology transforms digital designs, such as a CAD (Computer-Aided Design) file, into a physical object with unparalleled accuracy and repeatability. By eliminating the potential for human error, CNC machines can execute complex cuts, intricate geometries, and multi-axis movements that would be impossible to achieve manually. Processes like CNC milling, turning, and electrical discharge machining (EDM) allow for the creation of highly detailed parts efficiently and consistently. This makes Precision CNC Machining Services the cornerstone of modern manufacturing, enabling rapid prototyping and scalable production without sacrificing quality.

The Advantages of Partnering with a Professional Manufacturer

Choosing to work with a dedicated firm that excels in Professional Manufacturing offers numerous strategic benefits. Beyond access to state-of-the-art equipment, you gain a partner with invaluable expertise in materials science, engineering, and quality control. These experts can provide Design for Manufacturability (DFM) feedback, helping you optimize your designs to reduce costs, improve performance, and shorten production timelines. A professional partner implements rigorous quality assurance protocols at every stage, from material inspection to final verification, ensuring every part meets your exact specifications. This collaborative approach minimizes waste, accelerates time-to-market, and ultimately provides a superior return on investment, allowing your team to focus on innovation while leaving the complex production to the specialists.

The Future of Manufacturing is Precise and Professional

The trajectory of modern industry is clear: the future belongs to those who prioritize quality, accuracy, and efficiency. The principles of Professional Manufacturing, supported by advanced Precision Manufacturing Services and cutting-edge Precision CNC Machining Services, are no longer optional extras but the standard for excellence. By embracing these capabilities, companies can not only produce superior products but also drive innovation and maintain a competitive edge in a global marketplace that continues to demand perfection. As technology continues to evolve, the partnership between design ingenuity and manufacturing expertise will become even more crucial in shaping the world of tomorrow.