We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

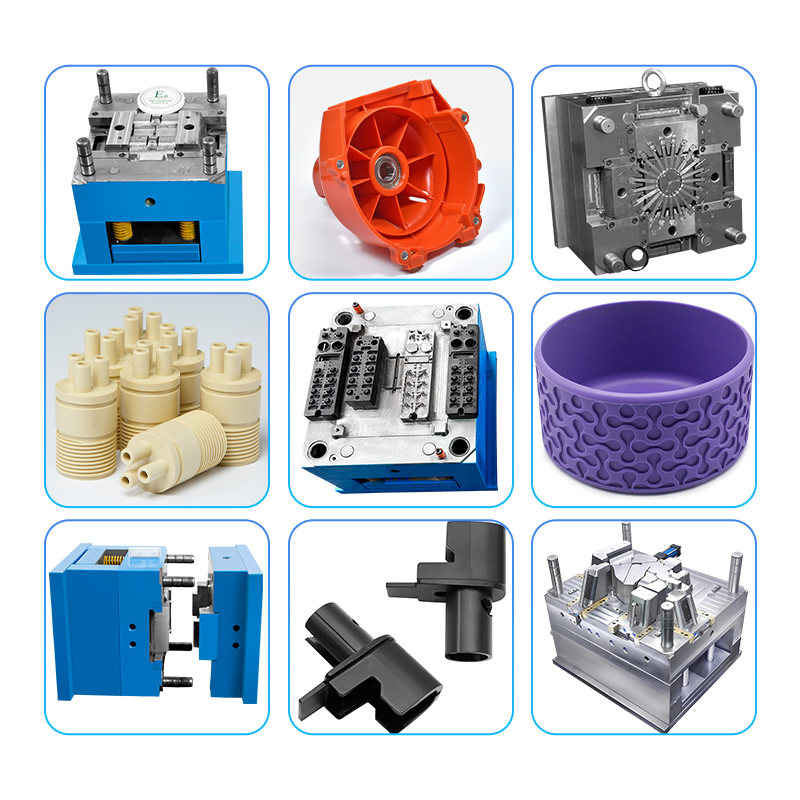

Our expertise includes:

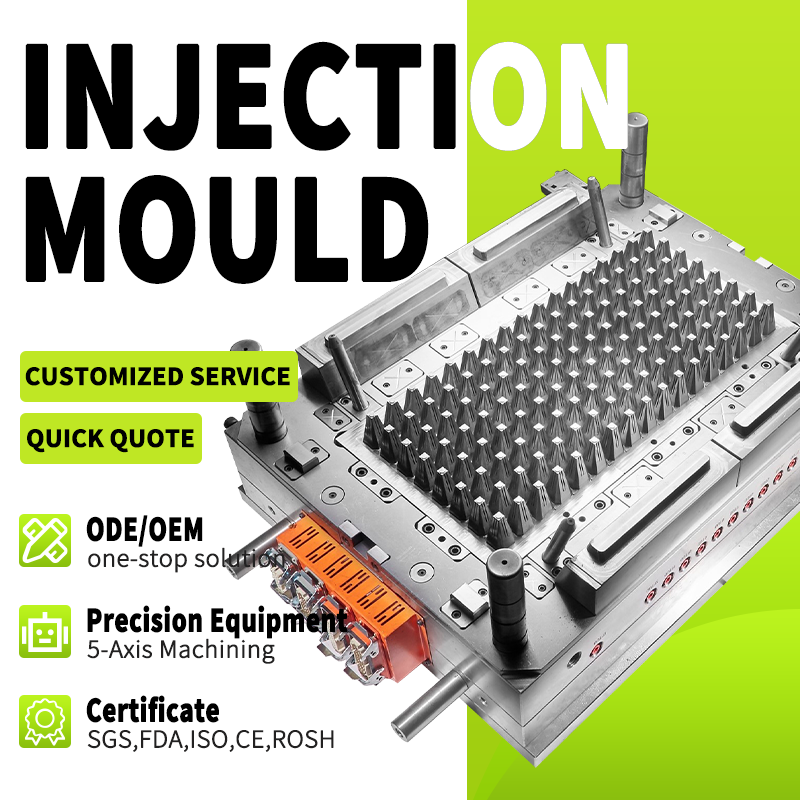

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In the world of modern manufacturing, turning a conceptual design into a tangible, functional component requires immense skill, advanced technology, and an unwavering commitment to quality. This is the domain of professional machining, a critical process that underpins nearly every industry, from aerospace to medical devices. It involves the controlled removal of material from a workpiece to create a finished part with precise dimensions and specifications. Without these sophisticated techniques, the complex products we rely on daily simply would not be possible.

What Defines Precision Machining Services?

Precision machining services are a specialized subset of manufacturing focused on creating components with extremely tight tolerances. This level of accuracy, often measured in micrometers, is non-negotiable for parts that must fit and function perfectly within a larger assembly. Achieving this requires a combination of highly skilled machinists, state-of-the-art equipment, and a deep understanding of material properties. Whether working with metals like aluminum and stainless steel, or advanced plastics and composites, these services ensure that every piece is produced with exceptional repeatability and accuracy. The core principle of precision machining services is to deliver consistent quality, ensuring that the thousandth part is identical to the first, meeting the most demanding engineering requirements.

The Power of Precision CNC Machining Services

The evolution of this field has been significantly driven by technology, most notably the advent of Computer Numerical Control (CNC). Precision CNC machining services utilize computer-programmed instructions to automate the control of machine tools like mills, lathes, and grinders. This automation brings unparalleled advantages, drastically reducing the potential for human error while increasing efficiency and production speed. CNC machines can execute complex, multi-axis movements to create intricate geometries that would be impossible to achieve with manual methods. As a result, precision CNC machining services are the backbone of rapid prototyping and large-scale production, enabling innovation and guaranteeing that every component adheres strictly to the digital design blueprint.

Industries Transformed by Professional Machining

The impact of professional machining is evident across a vast spectrum of industries. In the aerospace sector, it is used to create lightweight, high-strength components for engines and fuselages where failure is not an option. The automotive industry relies on it for everything from engine blocks to transmission parts, demanding high-volume production without sacrificing quality. In the medical field, biocompatible materials are machined into life-saving implants, surgical tools, and diagnostic equipment with flawless surfaces and exact dimensions. The electronics industry also depends on these processes for manufacturing custom enclosures, connectors, and heat sinks that protect sensitive components. Each of these applications highlights the essential role of professional machining in advancing technology and ensuring safety and reliability.

Selecting a Partner for Your Machining Needs

Choosing the right partner for your project is crucial to its success. When evaluating providers, it’s important to look beyond just capabilities. A top-tier partner will have a proven track record, robust quality control systems like ISO certification, and a team of experienced engineers and machinists. They should be able to offer guidance on material selection and design for manufacturability (DFM) to optimize your part for both performance and cost-effectiveness. A collaborative approach ensures that the final product not only meets but exceeds expectations. The future of manufacturing continues to evolve, but the foundation of quality, accuracy, and innovation provided by professional machining remains more important than ever.