We’re Guangdong Engineering Plastics Industries Group Co., Ltd. , a specialized manufacturer of custom molds and injection molding solutions with 26 years of experience serving global clients.

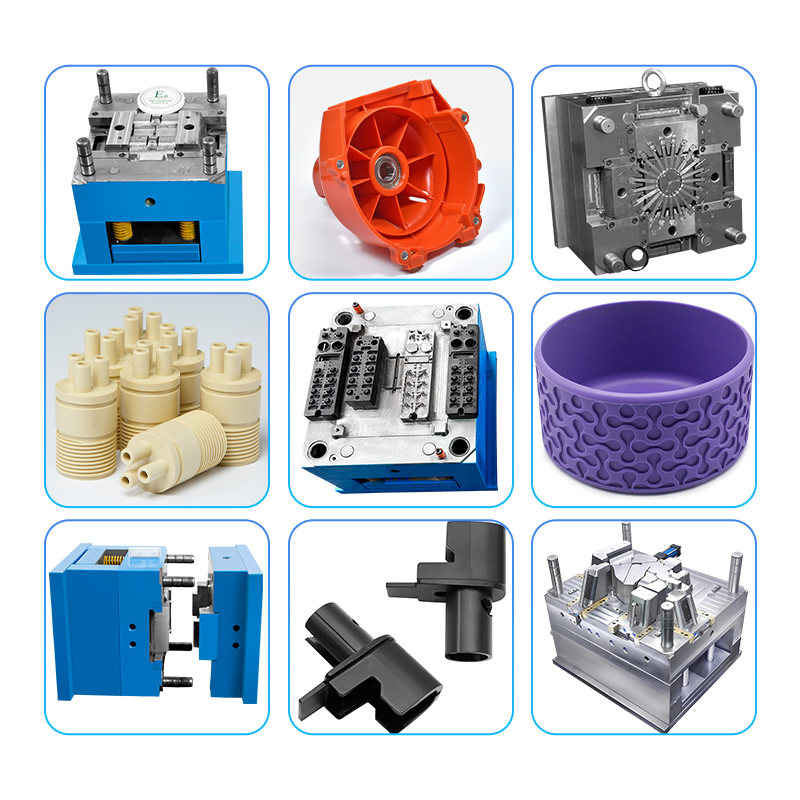

Our expertise includes:

*Complex Mold Design: Multi-cavity, hot-runner, and micro-molding capabilities

*Full-Service Production: From prototyping to high-volume manufacturing

*Material Options: Engineering plastics, LSR, biodegradable polymers, etc.

*Quality Assurance: ISO 9001-certified with strict tolerance control (±0.01mm)

We’ve successfully delivered projects for industries including aerospace, automotive, robotics , and medical devices.

Our factory specializes in high-accuracy CNC machining of plastic components, utilizing state-of-the-art computer numerical control technology to deliver exceptional dimensional consistency and complex geometries. We process a wide range of engineering-grade thermoplastics including PEEK, PPS ,PAI, PI, PBI,PTFE,Nylon, ABS, POM, UHMWPE, PE,PSF, PEI, PSU, etc, catering to industries requiring tight tolerances from automotive to medical applications.

Could we schedule a call to discuss how we can optimize your next project for quality, cost, and lead time?

Email:sales@gz-plastics.com

Tel: +8618588927610

Website:https://gz-plastics.com/

In our modern world, we are surrounded by countless objects made from plastic. From the device you're using to read this to the components in your car, plastic parts are an integral part of daily life. The primary manufacturing method responsible for this proliferation is a highly efficient process known in French as forme d’injection, or injection molding. This technology allows for the mass production of complex and identical parts with remarkable speed and precision, making it a cornerstone of contemporary industrial manufacturing.

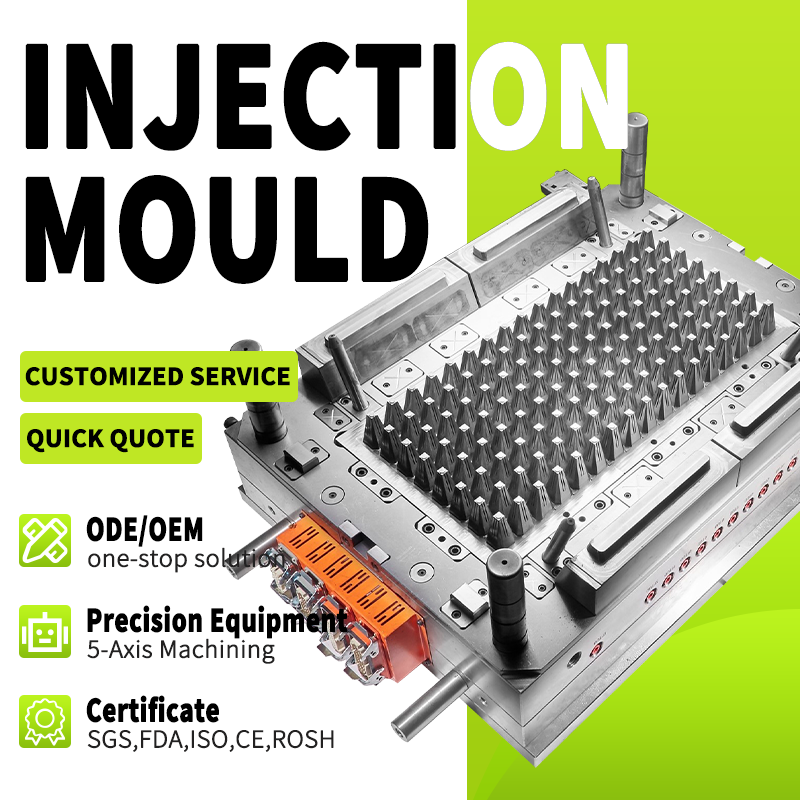

The Heart of the Process: The Injection Mold

At the very core of this manufacturing technique is the mold itself, what one might call une forme d'injection en plastique. This is not a simple container; it is a highly engineered, custom-made tool, typically machined from durable materials like steel or aluminum. The mold is comprised of two main halves: the cavity half (A-side) and the core half (B-side). When these two halves are pressed together under immense pressure, they form a hollow space that is the exact negative shape of the part to be produced. The design and construction of this mold are critical, as its precision and durability directly determine the quality, consistency, and finish of the final plastic parts. Intricate features, complex geometries, and specific surface textures are all built into the mold, showcasing the advanced engineering required for this tool.

The Manufacturing Cycle: From Pellet to Part

The injection molding process is a cyclical one, designed for high-volume production. It begins with small plastic pellets being fed into a hopper, which then directs them into the barrel of the injection molding machine. Inside the barrel, a large reciprocating screw heats, melts, and pressurizes the raw material, transforming it into a molten state. Once the mold is securely clamped shut, the screw injects this molten plastic into the mold cavity at high pressure. The plastic fills every nook and cranny of the mold. The next crucial phase is cooling; the mold is maintained at a controlled temperature, allowing the molten material to solidify and take its final shape. Once sufficiently cooled, the mold opens, and an ejection mechanism pushes the finished part out. This cycle, which can take anywhere from a few seconds to a couple of minutes, repeats seamlessly to produce thousands or even millions of identical parts en plastique.

Why Injection Molding is a Dominant Force

The widespread adoption of the forme d’injection method is due to its numerous advantages. Its primary benefit is scalability and cost-effectiveness for mass production. While the initial investment for creating a custom mold (the une forme d'injection en plastique) can be substantial, the cost per part becomes incredibly low as production volume increases. The process also generates very little waste, as excess material can often be reground and reused. Furthermore, it offers exceptional design flexibility, allowing for the creation of incredibly complex parts with high precision and repeatability. This versatility is why injection molding is used across nearly every industry, producing everything from automotive dashboards and medical syringes to toy bricks and electronic casings en plastique. This powerful technology continues to drive innovation in product design and manufacturing.